Intelligent P&IDs that connect to your 3D design

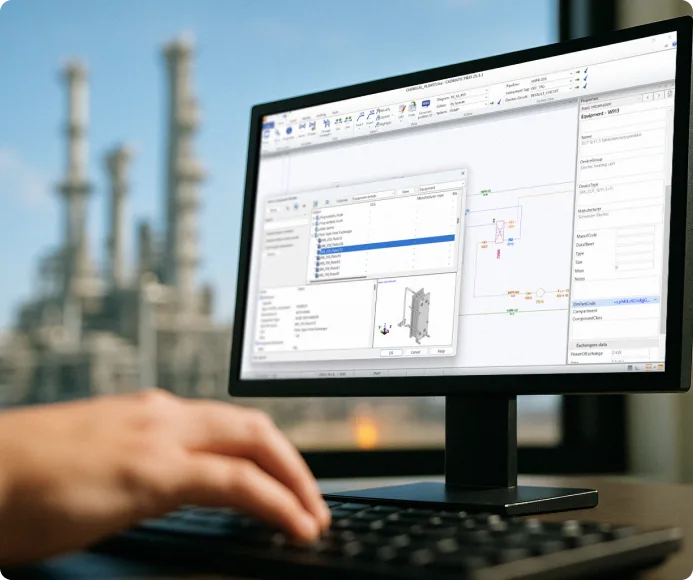

Design, edit, and manage process diagrams with unified data across 2D and 3D models.

Overview

Diagrams with real data connections

CADMATIC P&ID enables fast and accurate creation of process and instrumentation diagrams with unified data across your 3D models and electrical diagrams. Set design rules once and benefit from accurate data in a shared data environment. Less manual work and faster workflows for your project.

- Create intelligent, data-rich diagrams

- Maintain full design consistency with 3D models

- Customize library of standardized symbols to your project needs

- Reuse components across multiple projects

Benefits

Why choose CADMATIC P&ID

-

Work faster with smart tools

Speed up diagram creation with intelligent symbols and auto-connect features. -

Link diagrams to 3D and Electrical

Ensure data consistency across all design stages with intelligent workflows. -

Minimize design errors

Built-in validation ensures consistency and accuracy at every step.

Features

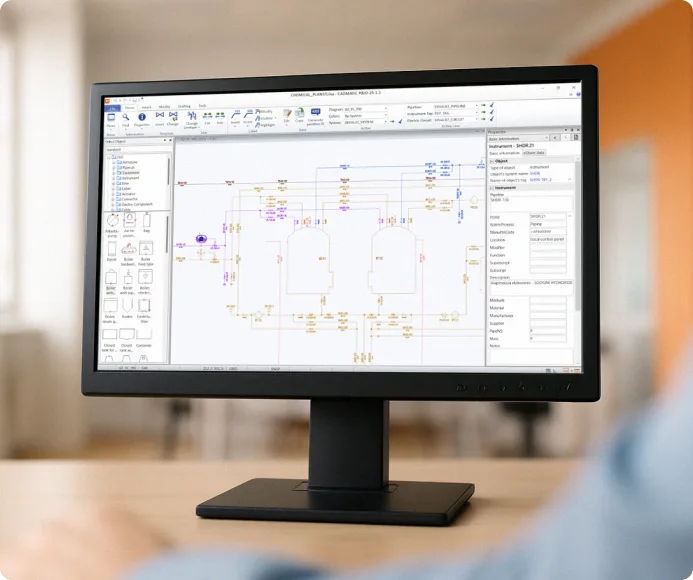

Create intelligent schematics that link to your 3D models

-

Intelligent diagram editor

Design P&IDs, PFDs, and schematic diagrams using data-rich symbols and connections. Symbols and connections automatically store and update object properties to ensure data consistency throughout the design process.- Auto-connect and drag features

- Symbol libraries with data rules

- Accurate data through consistency checks

-

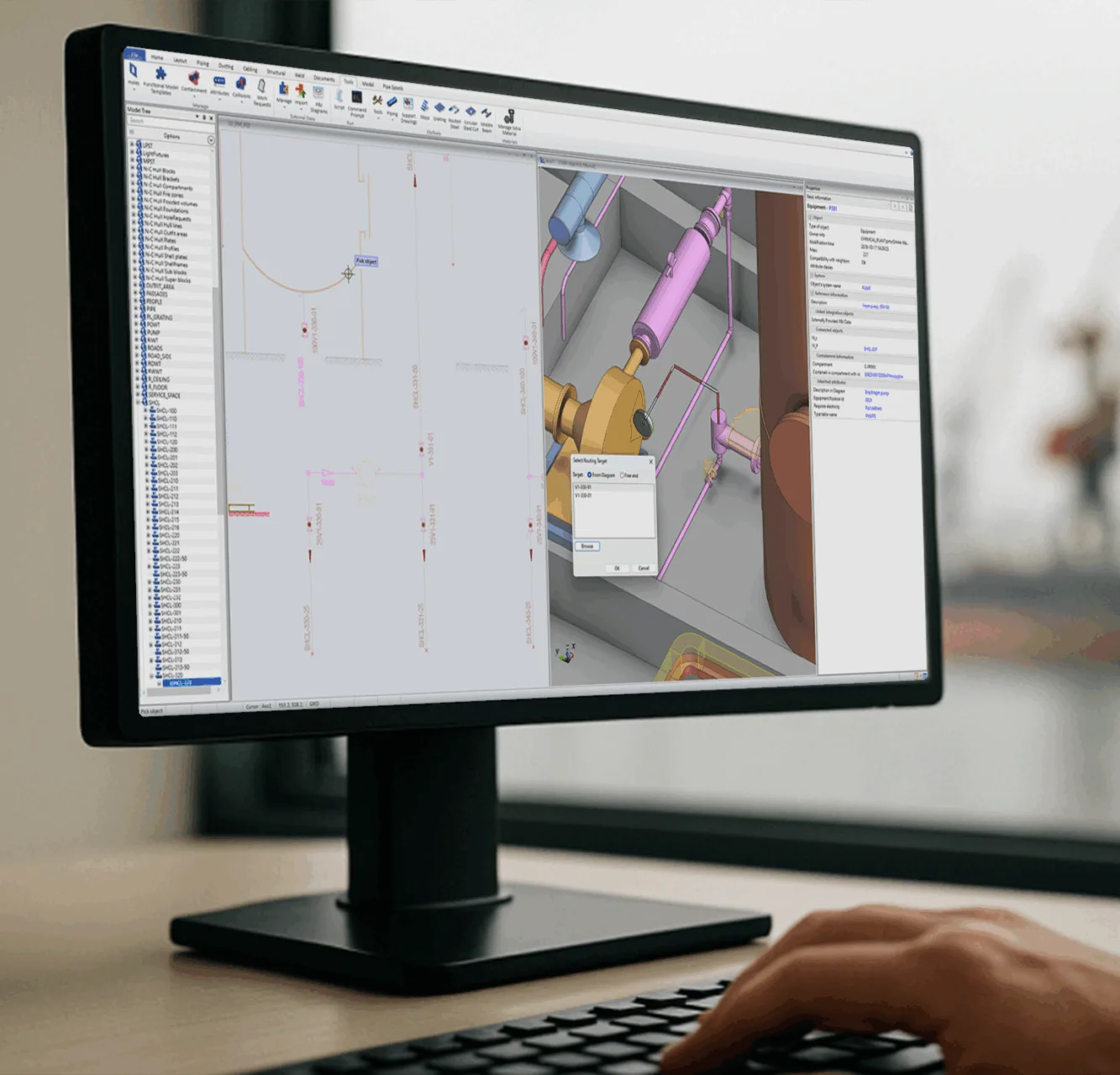

Built-in data connectivity to 3D

Connect your P&ID diagrams seamlessly to your 3D model. CADMATIC P&ID ensures full design traceability and error-free handover by maintaining consistent object IDs and bi-directional data flow between diagrams and 3D components.- Bi-directional data synchronization

- Unique object tagging supported with position ID generation

- Highlight 3D model progress in P&ID

- Data visualization with colors

-

Streamlined project setup and reuse

Standardize workflows with templates and projects defaults during setup. This way admins enable designers to work faster and with higher accuracy, as well as reuse the whole design diagrams, or any smaller units in processes.- Library-based design

- Admin-defined setup and customizable libraries

- Supports templates and standards such as ANSI/ASME, EN, DIN, and more

- Reuse across disciplines and projects

What customers say about Cadmatic

“The integration of 2D and 3D graphical elements with engineering data led to a drastic reduction in errors and the time required to generate lists.”

Federico Busquier

“The main reason we started using CADMATIC software was to reduce errors during the construction phase by designing with a common database. Using CADMATIC has had a positive effect on our working methods”

Paolo Fantini

Technical Manager

Frequently asked questions

Can multiple designers work on the same project?

Yes. The multi-user environment allows several designers to work on the same model simultaneously, with real-time synchronization and change tracking.

What file formats are supported for export?

Cadmatic supports multiple industry-standard formats such as DXF, DWG, and STEP. You can also export to IFC and use integrations with PLM systems.

Explore more resources

See all resourcesReady to get started?

Discover related products

See all products