Smart shipyard assembly planning – How Seaspan cut manual workload by 75%

“By significantly reducing manual effort, our planners can now thoroughly review the output and ensure the plans truly support production efficiency – with parts sequenced and installed at the right stage.”

Matthew Taylor

Senior Manager – Design Build

Cadmatic use in a nutshell

Customer challenge

- Manual, experience-based assembly planning leading to inefficiencies and delays.

- Lack of integration between CAD and planning systems, missing clear sequencing.

- High workload for planners, requiring significant manual effort.

Cadmatic solution

- Implementation of a rule-based, automated assembly planning process, reducing reliance on manual work.

- Integration of Stage of Construction (SoC) sequencing, optimizing work location and sequencing.

- 75% automation of planning tasks, significantly reducing workload.

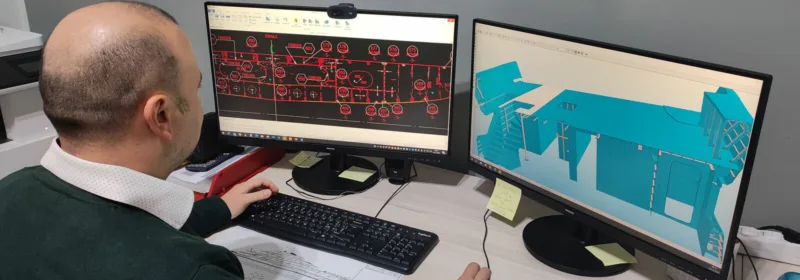

Shipbuilding has long been a complex orchestration of planning, sequencing, and execution. At Seaspan, one of North America’s leading shipyards, assembly planning was a highly manual and experience-driven process. That meant planners had to rely on their knowledge of the shipyard to determine where and when work should take place.

According to Matthew Taylor, Senior Manager – Design Build at Seaspan, the process used to be highly manual and required planners to stay fully focused. Creating an assembly and selecting its parts involved a lot of typing and mouse clicks.

“This made errors likely,” Matthew explains. “Manually choosing the correct parts from a model with hundreds of thousands of components is incredibly complex.”

By implementing a rule-based, automated assembly planning system, Seaspan has transformed how work is structured, reducing manual workload and unlocking substantial cost savings. Here’s how it happened – and what it means for the future of shipbuilding.

From manual processes to digital precision

Traditionally, Seaspan’s assembly planning was handled manually. Planners would determine which parts were needed, assign work locations, and sequence tasks based on experience. While effective, this approach was time-consuming and prone to errors.

With Cadmatic’s assembly planning toolset, that process is now 75% automated. Instead of manually deciding where each component should go, the system leverages Stage of Construction (SoC) sequencing to define what work is done, where, and when.

“Automated planning has allowed our planners to focus on what they do best,” says Matthew. “By significantly reducing manual effort, they can now thoroughly review the output and ensure the plans truly support production efficiency – with parts sequenced and installed at the right stage.”

Bridging the gap between CAD and planning

Traditionally, shipyards have relied on CAD software to define what needs to be built and ERP systems to manage who does the work and when. But the crucial questions of where work happens and what happens next were left to individual planners.

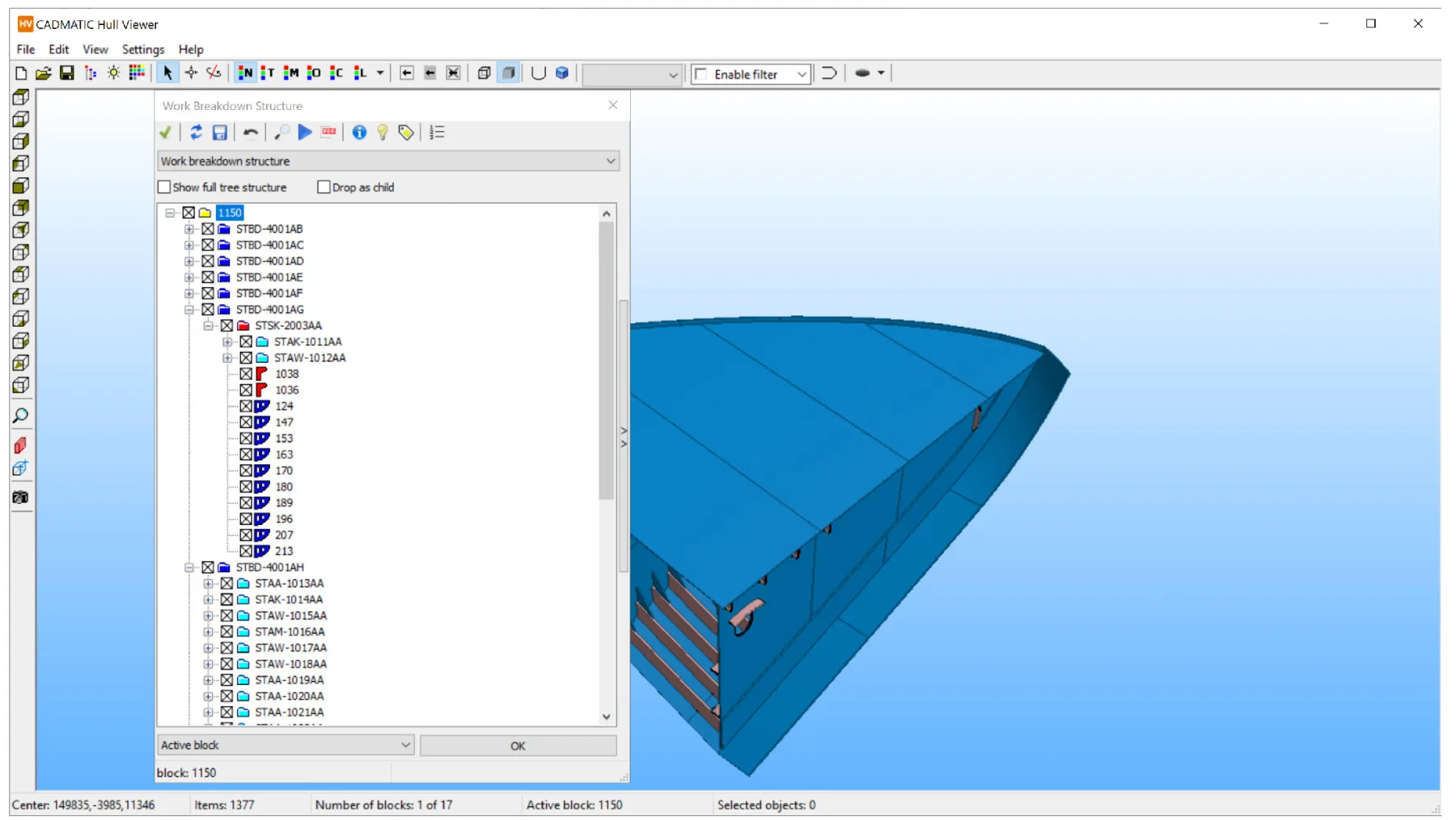

Cadmatic’s solution closes this gap by integrating 3D design data with structured work breakdown sequences. The result? A structured, rule-based approach that eliminates uncertainty and ensures every part follows an optimized SoC journey – from cutting and forming to panel assembly, block construction, and final outfitting.

The power of automation in shipbuilding

One of the most significant advantages of Cadmatic’s toolset is its ability to automate sequencing and part allocation. The system evaluates part attributes, such as material type, size, and shape, and determines the most efficient production path.

Key benefits

- 75% reduction in manual planning effort – allows planners to focus on review and optimization of Assembly Plans.

- Significant cost reduction per project by minimizing delays and errors.

- Just-in-time delivery reduces material storage needs and improves workflow efficiency.

A structured approach to naming and tracking

Seaspan’s implementation of Cadmatic’s system also leveraged a highly detailed naming convention for parts and assemblies. This structured approach ensures that workers can immediately see what needs to be done, where, and at which stage – eliminating reliance on tribal knowledge.

The name itself contains information about the assembly stage location and the sequence of construction. For example, a block assembly consists of panels that are first assembled at the panel line, along with loose parts. These parts carry the logic of where they were built and where they need to go next. This approach has enabled Seaspan to build more efficiently with reduced stock while enhancing traceability.

“With a stable and consistent build methodology, we can now apply rule-based automation to efficiently generate assembly plans for repeatable products and processes,” says Matthew. “This opens the door to completing more value-adding planning tasks earlier in pre-production, which can potentially reduce overall project timelines.”

A game-changer in the shipbuilding industry

While initially designed for Seaspan, Cadmatic’s solution is not a one-size-fits-all product. It is a configurable process that can be tailored to other shipyards. The toolset has sparked curiosity and is under investigation at major shipyards, such as ThyssenKrupp Marine Systems (tkMS), showcasing its scalability and adaptability.

Unlike traditional PLM (Product Lifecycle Management) systems, which require manual selection, Cadmatic’s automation-first approach sets it apart. By integrating graphical feedback with automated sequencing, it offers a level of precision and efficiency unmatched in the industry.

What’s next? The future of assembly planning

Cadmatic isn’t stopping here. The next step is to develop a unified assembly planning tool that fully integrates hull and outfitting into one seamless workflow. This would eliminate the need for separate planning processes and make adoption even easier for shipyards worldwide.

In the long run, this standalone sequencing tool will simplify training requirements, allowing planners to focus on strategy and execution rather than software complexity.