Power & energy

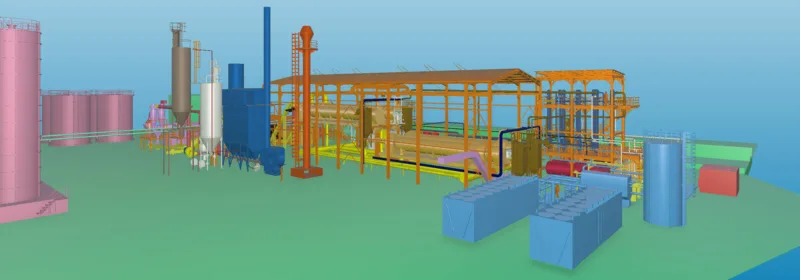

Design and manage energy facilities with advanced tools for fast, sustainable delivery.

Smarter tools for operating complex energy assets

As an owner-operator in the power and energy sector, you need more than just project deliverables. You need data continuity, asset visibility, and tools that support safe, efficient maintenance. Cadmatic helps you take ownership of your plant information, enabling smarter projects, safer maintenance, and seamless digitalization. From early engineering to daily operations, we connect people, tools, and systems in a unified environment.

-

Gain full ownership and control of your engineering data

-

Collaborate seamlessly with multiple EPCs and contractors

-

Use a live digital twin that evolves from design to operations

-

Eliminate handover gaps with a ready-to-use digital twin

-

Keep electrical documentation accessible and up-to-date

-

Plan and execute maintenance with accurate, up-to-date data

Benefits

-

Own your plant data for the long term

No vendor lock-in – your data, your structure, your control -

A ready-to-use digital twin at handover

Skip rework – move straight from project to operations -

Maintenance made more efficient

Plan inspections and upgrades with accurate, visual data

Explore more success stories

See all storiesProducts

Bring all project and asset data into a unified, visual environment enabling full transparency.

Efficiently create, manage, and maintain engineering data and documentation throughout the project lifecycle.

Model plant layouts, piping, and steel structures with precision using professional tools for 3D design and documentation.

Streamline electrical, automation, and instrumentation design with powerful and integrated tools.

Design, edit, and manage process and instrumentation diagrams with unified data across 2D and 3D models.

Keep project delivery on time and on budget. Tackle large, complex industrial projects efficiently,

Ready to get started?

Who we serve

Boost productivity, reduce errors and win more projects by delivering high-quality ship and plant designs faster.

Gain full control of complex project data, ensure smoother collaboration, faster handovers, and on-time delivery.

Make smarter and faster decisions across your asset lifecycle thanks to accurate digital plant data and visual insights.

Frequently asked questions

Can Cadmatic help improve collaboration between teams?

Yes. Cadmatic creates a shared digital environment that connects engineering, operations, and maintenance teams. It ensures all stakeholders access the same up-to-date asset data, enhancing coordination and reducing silos.

Can I host Cadmatic solutions on-premises or in the cloud?

Yes. Cadmatic offers flexible deployment options, allowing you to choose on-premises installation, private cloud, or hybrid setups to meet your IT and data security requirements.

Is Cadmatic software interoperable with other systems?

Absolutely. Cadmatic supports integration with common engineering and asset management systems. Our open interfaces and data standards ensure smooth interoperability across your digital ecosystem.

How does Cadmatic support real-time project monitoring?

CADMATIC eShare creates a visual, data-rich 3D environment that connects design, documentation, and systems in real time. It gives teams and stakeholders full visibility into project status, helping them track progress, inspect models, and make faster, well-informed decisions.

By centralizing all project and asset data, eShare improves collaboration, reduces risk, and supports better outcomes across the entire lifecycle. After handover, it continues to add value as a digital twin – streamlining maintenance, operations, and future upgrades.

What happens to my data after project handover?

Cadmatic ensures that your engineering data doesn’t disappear into folders or PDFs after handover. With tools like CADMATIC eShare, you can access all design models, documents, and asset data in one connected platform. It provides a visual digital twin that lets you search, navigate, and use the data throughout operations—whether for maintenance planning, inspections, or audits. Your information stays structured, traceable, and usable long after commissioning.