Driving construction projects forward with digital twins

Industrial EPC projects involve many parties working in parallel across different systems, documents, and schedules. When engineering updates and site execution are not optimally coordinated, the impact shows up quickly in delays, rework, and rising costs.

A practical digital twin helps by keeping the 3D model and project data connected and easy to use in daily construction work. The goal is to give every team the same, real-time view of what’s planned, what’s installed, what’s verified, and what needs attention next.

Next, we show how this works in practice and introduce Bonatti’s construction projects as a real-world example.

Moving from complex data to clear visibility

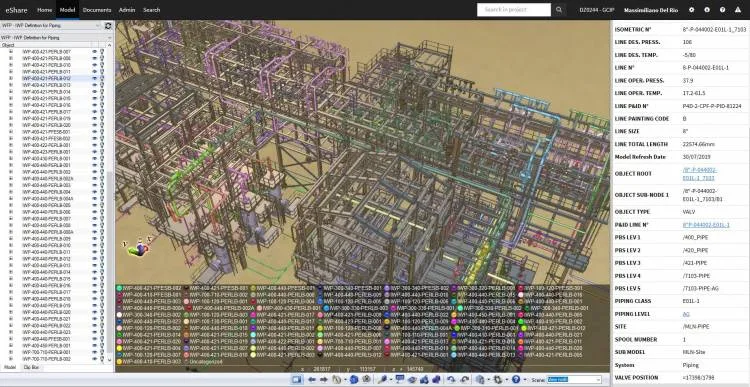

In construction, a digital twin works when it connects the 3D model with up-to-date project information such as schedules, materials, quality control activities, and issue tracking. That creates a single model-based view of progress and constraints, without chasing updates across tools.

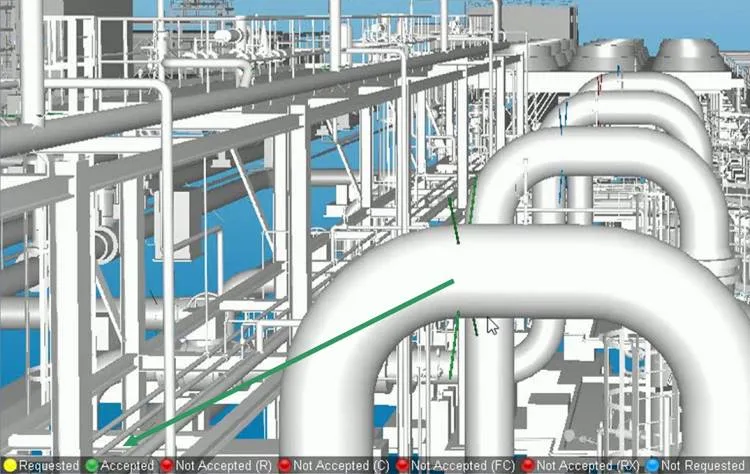

With a model-based view, teams can see installation status and delays through color-coded 3D views. Changes and instructions are shared so everyone works from the same, current project information, which supports faster coordination between engineering, planning, and the site.

A digital twin also supports construction planning by defining and tracking work packages directly in the model. Instead of relying on spreadsheets alone, teams can group model objects by scope, assign work, and follow progress directly in the model.

This approach supports workface planning by making the required inputs available to the crew before work starts, such as drawings, materials, procedures, permits, and equipment.

How Bonatti uses CADMATIC eShare in construction

Bonatti, an international oil and gas general contractor, adopted CADMATIC eShare to boost the efficiency of its constructability and construction phases. A key reason it turned to Cadmatic’s digital twin solution was its ability to track construction statuses directly in the 3D model.

Over and above visibility, the benefit for Bonatti is clearer execution. By combining progress, quality control activities, and construction constraints in one model-based view, the team can identify interferences and potential schedule impacts early. This helps to prevent errors, delays, and avoidable cost overruns. The same visual approach also improves decision-making on site, since managers can understand the real situation in a single view instead of relying only on reports and tables.

Bonatti applies color coding in eShare to present installation progress and quality control activities, including erection certification, piping pressure testing, plant mechanical completion, and handover tracking.

Another priority for Bonatti is supporting the site in managing and tracking specific activities, including workface planning. The intent is to remove execution constraints and ensure that required inputs are monitored and available to the crew assigned to a work package.

Clear visibility for fabrication and welding data

Bonatti also uses eShare to visualize piping fabrication feasibility in the 3D model, and to display welding execution and examination status as part of construction follow-up.

“We now build things correctly the first time because we always have access to up-to-date information and drawings. With eShare, everything is centralized in a single platform,” one project lead at Bonatti said.

Read the full Bonatti success story here

Digital twin value in construction comes down to daily execution support:

- One visual view of progress, constraints, and quality status

- Faster coordination between the office and the site

- Less rework through clearer status tracking and more reliable inputs to field crews