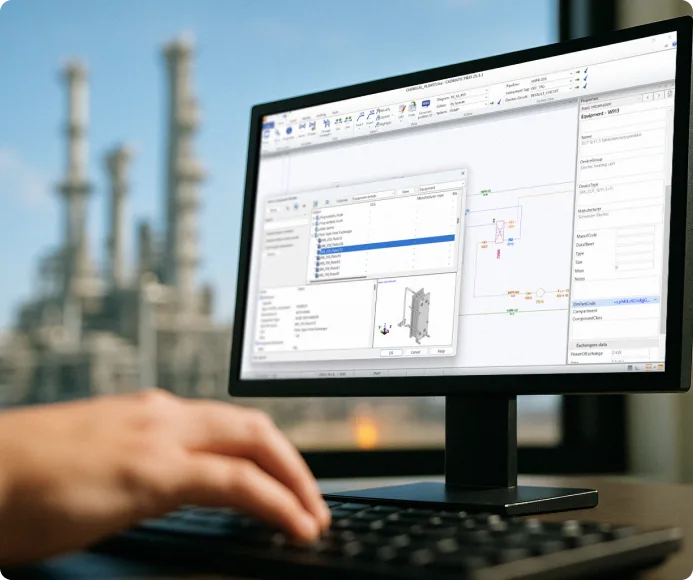

Industrial plant engineering software

Engineering the future of industrial plant design

Whether you’re designing, building, or operating an industrial plant, Cadmatic helps you work smarter and deliver better results. Our industrial plant engineering software supports the entire plant lifecycle – from detailed and conceptual plant design to construction, commissioning, and operations. With connected data, real-time collaboration, and a digital twin that adds long-term value, you can reduce risk, cut delays, and move projects forward with confidence.

Uniting design and data in one environment

Speed up design with one software platform that connects teams, tools, and data.

Minimizing design errors and rework

Design faster with fewer errors thanks to automation and built-in quality checks.

Ensuring smooth project handover and continuity

Keep your project moving with connected data and uninterrupted workflows.

Keeping plant engineering information accurate and accessible

Access reliable plant data anytime to support safe, efficient operations.

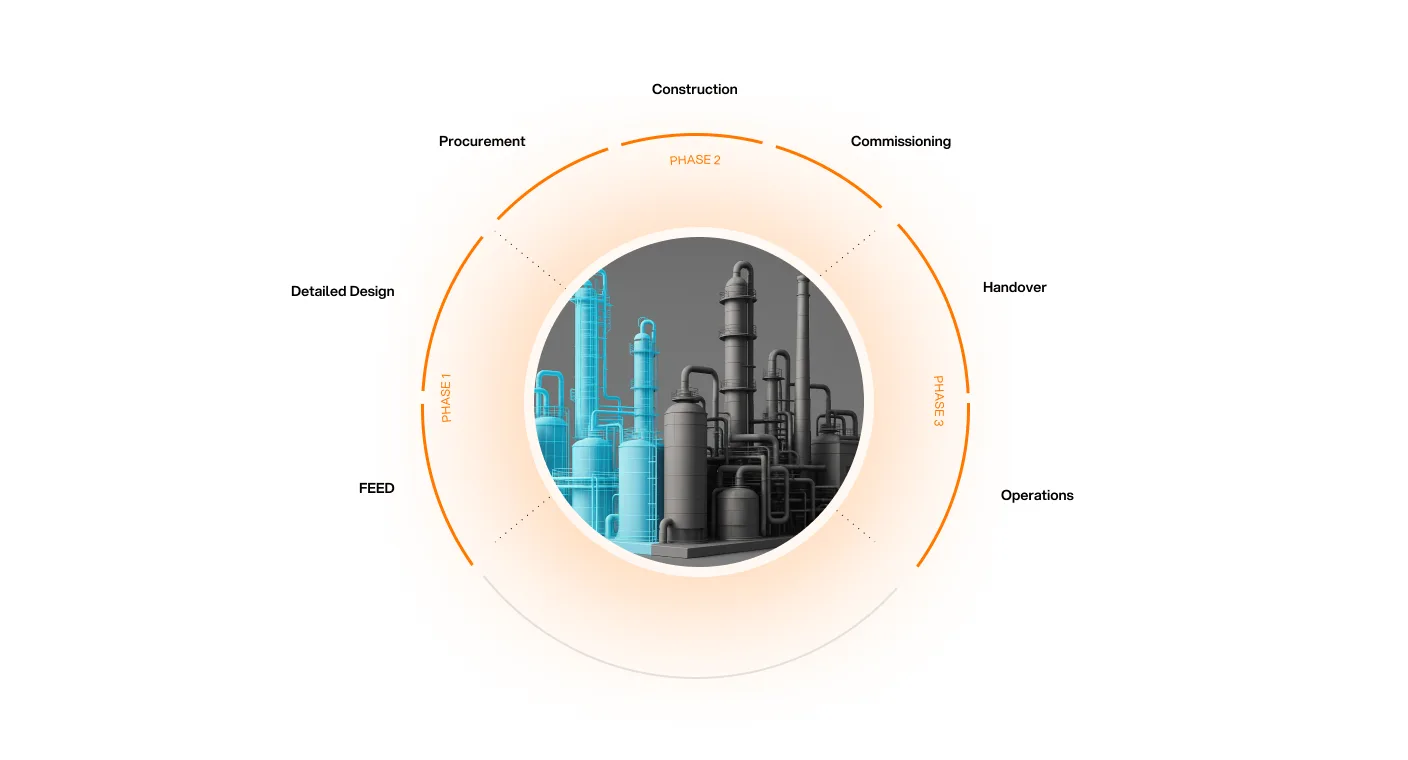

Industrial Plant Lifecycle

From design to operations, you stay in control with connected data, smart collaboration, and tools for digitalization – now powered by AI.

Unify 3D, P&ID, and electrical design in one platform. Collaborate in real time, cut design iterations, and keep projects on schedule, within budget, and fully compliant.

Keep construction, and commissioning on track with real-time data and dashboards. Gain instant insight to act faster, reduce surprises, and keep every stakeholder aligned.

Operate smarter with a connected digital twin. Access accurate asset data instantly, streamline maintenance and inspections, boost safety, and extend asset life with confident, informed decisions.

Complete plant engineering software

-

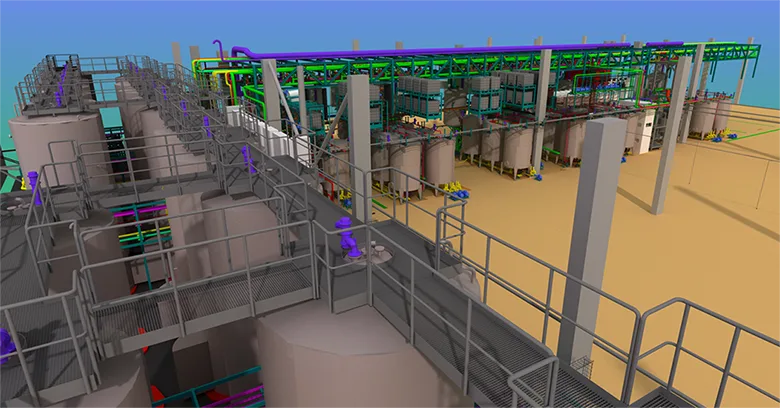

All-in-one plant engineering software

Providing a unified plant engineering platform, Cadmatic simplifies engineering across disciplines and locations. Automated workflows, shared data, and integrated tools reduce manual work and rework, helping you stay within schedule and budget. With a single source of truth and full traceability, your teams can work more efficiently, validate designs faster, and ensure compliance – all while keeping engineers focused on high-value tasks.- Unified tools for plant, P&ID, and electrical design

- Smart automation and fewer design iterations

- Real-time collaboration with one source of truth

-

Smarter construction, smoother handover

Cadmatic helps you keep projects on track with real-time status tracking, centralized data, and visual dashboards. Project managers gain instant insight into design progress, material readiness, construction, and commissioning activities. Built-in change control minimizes surprises and supports continuous improvement. With better visibility, you can make informed decisions faster and keep stakeholders aligned every step of the way.- Real-time project status and KPIs

- Based on exact data – level 5

- Visual dashboards for clear decision-making

-

Operate smarter, longer

With up-to-date digital twins and centralized asset data Cadmatic ensures reliable plant operations. Easy access to accurate information supports maintenance, inspections, and modifications. Boost your safety, efficiency, and long-term asset performance.- Connected digital twin: Access real-time, accurate asset data in 3D to support smarter maintenance and planning.

- Instant access to documentation and information from other business systems: Save time and reduce risk during inspections, repairs, and audits.

- Improved safety and decision-making: Navigate complex facilities with confidence and make informed operational choices.

Ready to get started?

Explore more resources

See all resourcesFrequently asked questions

Can we build a digital twin if we’re already mid-project or in operation?

Yes. Cadmatic allows you to create or enhance a digital twin using existing models, documents, and point cloud data. You don’t have to start from scratch, your current systems can be integrated.

How can Cadmatic help reduce project delays and rework?

Our tools include built-in clash detection, rule-based design automation, and real-time collaboration. These features help you catch errors early, keep teams aligned, and stay on schedule.

How easy is it to share data with suppliers and contractors?

Very easy. Cadmatic uses open formats and browser-based tools like eShare to share models, documents, and updates securely with external stakeholders – no CAD license needed.

Can Cadmatic support multi-discipline collaboration?

Yes, Cadmatic enables smooth work sharing across disciplines and locations with built-in collaboration tools and centralized data access.

Can I host Cadmatic solutions on-premises or in the cloud?

Yes. Cadmatic offers flexible deployment options, allowing you to choose on-premises installation, private cloud, or hybrid setups to meet your IT and data security requirements.