5 steps to keep your shipbuilding documents on track – from draft to delivery

Designing a ship is complex. Managing the documents that come with it shouldn’t be.

If you’ve ever lost time chasing down the right version of a drawing, wondering who’s supposed to review what, or dealing with delays because someone missed a markup, you’re not alone. Document workflows are the quiet source of chaos in shipbuilding and are rarely as smooth as they should be.

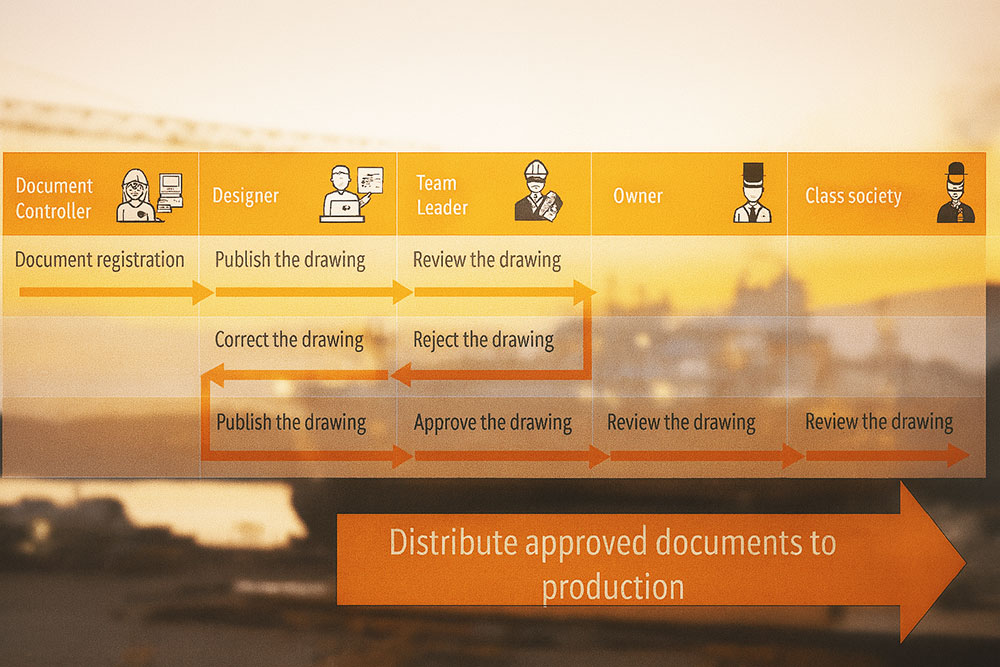

Let’s take a closer look at what a CAD document’s life looks like when a shipbuilding PLM solution is involved and why it matters for people like you.

Documents don’t manage themselves – people do

Every shipbuilding project produces thousands of documents, from 2D layouts to complex 3D models. But behind each of them is a chain of people including document controllers, designers, team leads, and external stakeholders. When tools are disconnected and processes unclear, miscommunication is inevitable.

CADMATIC Wave steps in as a central hub. It not only stores documents, but also guides them through their entire life cycle, from registration to review and to release.

Step 1 – Registering the document

It starts with the document controller. Their role is to define what needs to be created, by whom, and by when. Using Wave, they can:

- Create document cards with prefilled attributes

- Link documents to systems, rooms, or equipment

- Import data from Excel or templates

- Set expected workflows (for example, “review by yard, owner, class”)

- It’s a structured way to make sure everyone starts on the same page – and stays there.

Step 2 – Request goes to the designer

Once the document is registered, the designer gets a notification in their dashboard indicating that a new drawing is expected.

They open the task, and the document card is already waiting with all the metadata, project structure, and deadlines needed. Even better, the CAD drawing title block is automatically populated with the correct information. The designer simply focuses on doing the work, not duplicating data or digging through files.

Step 3 – Internal review by the team lead

After the drawing is published, the team lead steps in. In Wave, they can open the drawing, add markups directly, assign issues to the designer, and, if needed, reject the document.

Let’s say the drawing shows a heat exchanger colliding with a pipe. The team lead highlights the problem, writes a quick instruction (“Move 1m to +Y”), and sends it back. All this happens in one interface, with nothing getting lost in email threads or forgotten comments.

The designer is instantly notified of the issue in Wave and fixes the model in CAD. A few clicks later, the updated drawing is published back for review.

Step 4 – External approvals made easy

Once the internal team approves the document, Wave automatically triggers the next step, the owner or class society review.

Because access is role-based, external stakeholders only see the documents meant for them. They can review drawings, add comments, and approve or reject them without needing to understand internal systems or processes.

Step 5 – Ready for production

When everything is signed off, the final version is distributed to production. The document status and history are fully traceable, and everyone knows they’re working from the correct, approved file.

No guesswork. No version mismatches. Just clarity.

Why it matters

Managing shipbuilding documents isn’t just about file storage. It’s about keeping work moving without delays, confusion, or rework. CADMATIC Wave connects people, data, and processes across every role:

- For document controllers – Less manual tracking, more control

- For designers – Fewer disruptions, faster handoffs

- For team leads – Easier reviews, better issue tracking

- For owners and class societies – Smooth collaboration, fewer surprises

Shipbuilding is complex. Document management shouldn’t be.

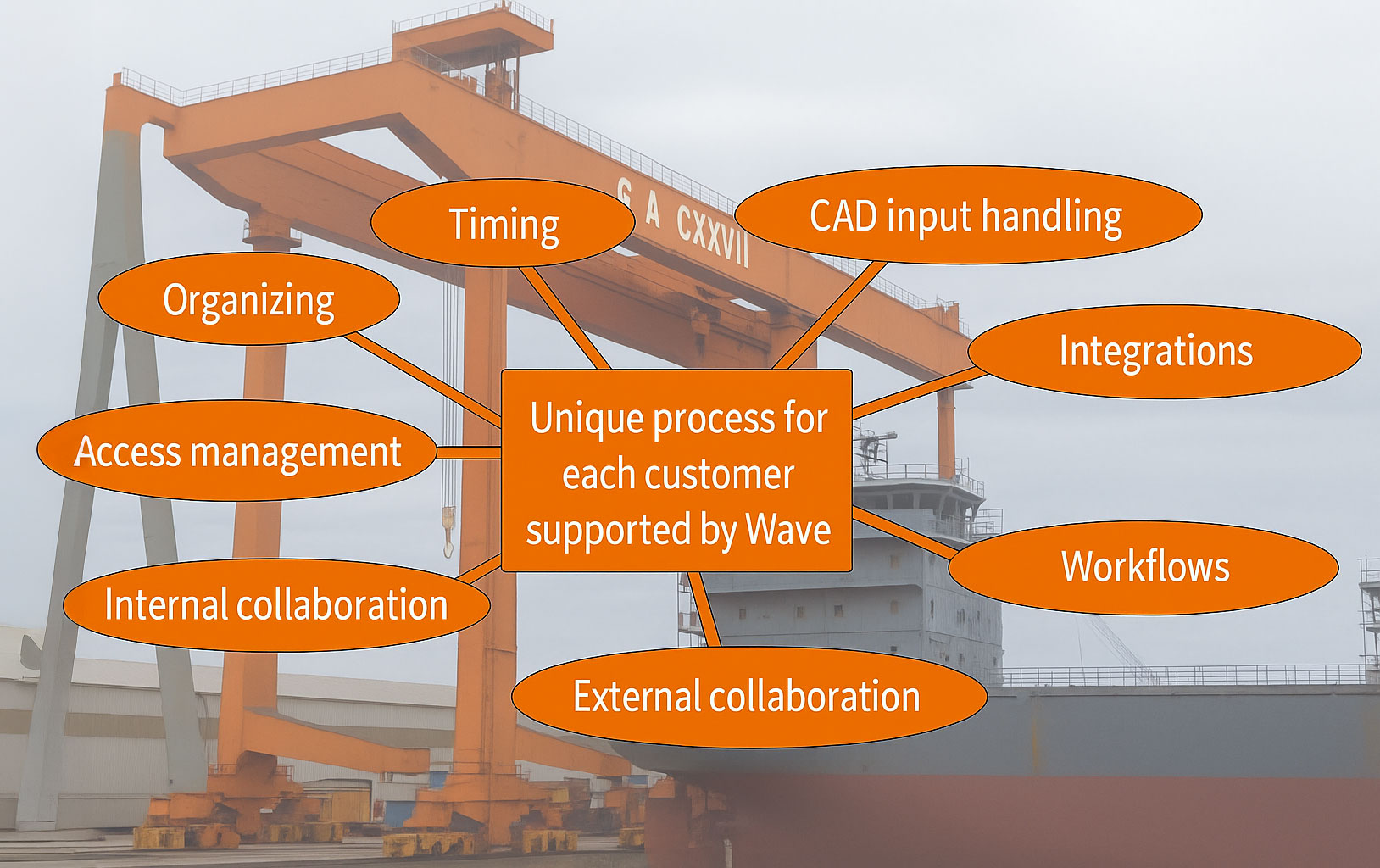

Wave doesn’t force you to change how you work. It adapts to your process, whether you’re managing reviews internally or coordinating across shipyards, owners, and suppliers.

The result? Less time with engineering document management, more time moving your project forward.