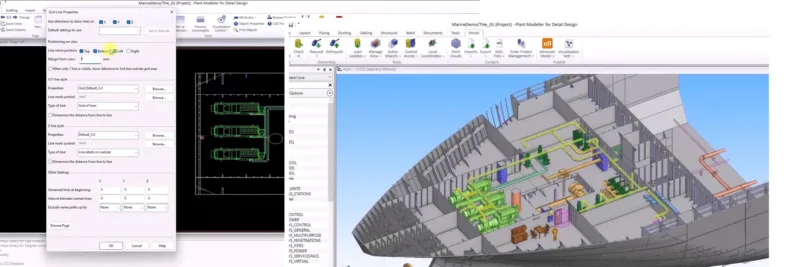

AI agents in plant design – paving the way for automated workflows and lower costs

Plant design projects involve constant coordination of equipment layouts, piping networks, structural elements and strict safety requirements. If you work in engineering or EPC projects, you know how challenging it is to manage massive amounts of data, meet industry regulations, and keep projects on schedule without costly errors.

AI-driven automation has the potential to change this reality. It can open the door to smarter workflows, fewer design revisions, and lower costs – giving engineers more time to focus on meaningful work.

AI agents as intelligent co-designers

AI agents are emerging as valuable co-designers that work alongside engineers to streamline workflows and improve decision-making. They can already interact with CAD tools, process documentation, and external systems to:

- Generate preliminary layouts based on project requirements

- Detect inconsistencies in engineering data by cross-checking multiple sources

- Optimize piping and equipment placement for efficiency, safety, and compliance

As AI capabilities mature and become part of everyday plant engineering software, EPCs and owner-operators will gain productivity, avoid costly revisions, and free up resources for innovation.

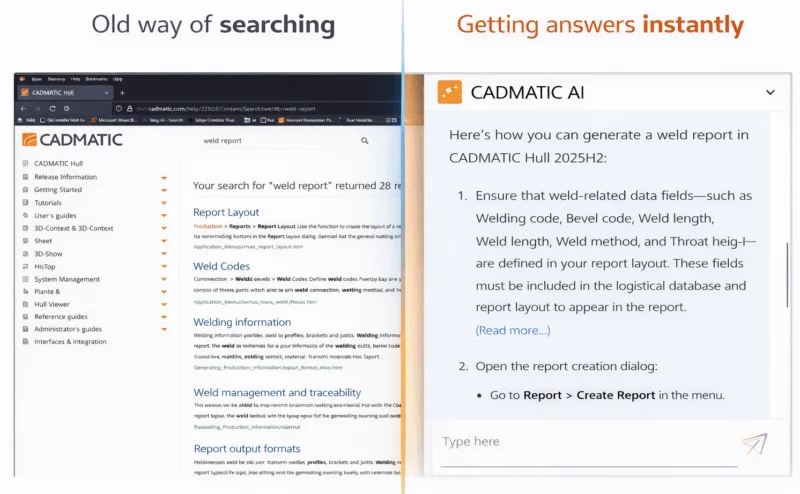

Smarter workflows with automated compliance and error detection

Compliance checks and manual validations are time-consuming and prone to oversight. Soon, AI agents will continuously validate designs against standards such as ASME, API, and ISO, flag potential safety risks early, and automate repetitive validation tasks.

By reducing these bottlenecks, engineers will have more time for creative problem-solving and innovation – instead of repetitive administrative work.

AI-driven efficiency across the entire project lifecycle

AI will not only transform the design phase but will also enhance the entire project lifecycle.

AI agents will enable automatic data exchange between design and construction, ensuring that engineered decisions are directly connected to prefabrication and construction activities. AI will help optimize material usage, minimizing waste and cutting costs, while also improving coordination between engineering, procurement, and construction teams. The result will be faster, more predictable, and more efficient project delivery – from concept to commissioning.

The future of AI in plant engineering

AI is not replacing engineers – it is giving them powerful new capabilities. By removing inefficiencies and automating routine work, AI frees up time for what matters most, which is designing safer and more efficient industrial plants.

At Cadmatic, we are bringing AI into 3D plant design to help you work smarter and stay ahead of the curve. We are investing in AI-powered capabilities to give EPCs and owner-operators new ways to reduce costs, improve quality, and deliver projects faster.