Documentation chaos – the 30% problem slowing down your plant

If there’s one thing every maintenance team relies on, it’s documentation. And if there’s one thing almost every plant struggles with, it’s keeping that documentation in order.

In complex industrial environments, documentation is everywhere: work instructions, wiring diagrams, safety plans, equipment manuals, as-built drawings, and more. Yet in many plants, these critical documents are stored in multiple systems. Some of these systems are digital, some printed, some passed between colleagues via email or memory sticks.

This means when a technician needs a procedure or drawing, it can take far longer to find than it should.

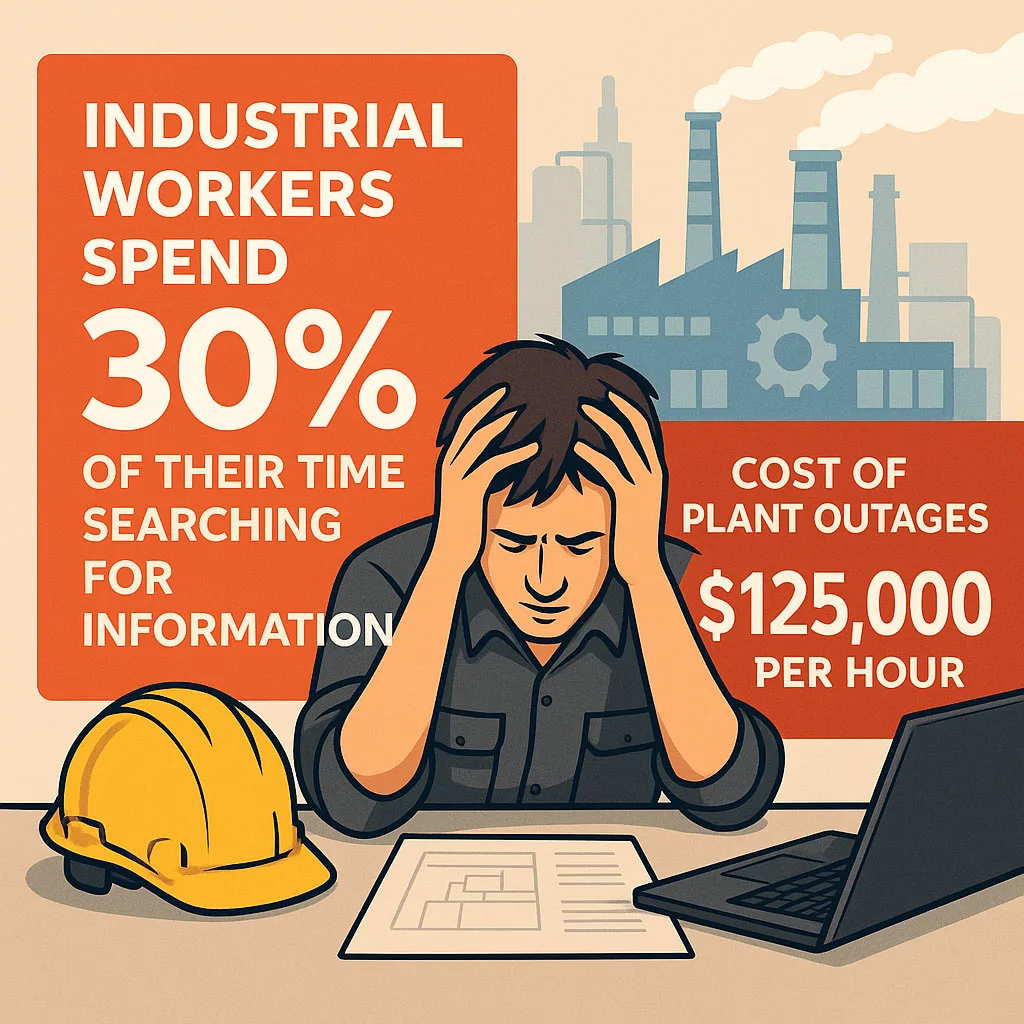

McKinsey reports that industrial workers spend up to 30% of their time just searching for documents – time that could be spent performing actual work. It’s a productivity issue that adds up quickly, especially when you consider how many maintenance tasks depend on having accurate, up-to-date information.

The reality of plant documentation – outdated, inconsistent, or just missing

Outdated documents can lead to rework, safety issues, or even compliance risks. And when different teams are working from different versions of the truth, coordination breaks down. These aren’t minor annoyances. They’re systemic inefficiencies that cost plants both time and money.

Documentation chaos becomes especially problematic during outages or inspections, when every delay eats into a tight schedule. And for new hires, navigating legacy systems or guessing which version is current makes onboarding unnecessarily difficult.

When a document bottleneck becomes a downtime driver

Even with the best maintenance planning, documentation issues create a ripple effect:

- Delays in job execution as workers confirm specs or safety steps

- Longer outage durations due to missing schematics or layout confusion

- Increased training time for new staff unfamiliar with legacy systems

- Audit headaches caused by version discrepancies or missing records

- Reduced trust in the systems that are meant to support technicians

An ABB downtime study highlights just how costly these issues become. With unplanned outages averaging $125,000 per hour, every unnecessary delay counts.

Verified documentation, exactly where it’s needed

CADMATIC eShare offers a smarter way to manage this challenge.

Instead of expecting technicians to dig through folders or log into multiple systems, eShare embeds documentation directly into the digital twin of your plant. Each object in the model is automatically linked to its associated documents, whether it’s a P&ID, a safety checklist, or a vendor manual. The plant becomes navigable, not just in physical space but in terms of information. This can be done equally from office desktops or mobile devices in the field.

That means that:

- Maintenance tasks are supported with the correct instructions – always the latest version.

- Safety plans are linked to the equipment they cover.

- Visual documents like P&IDs, wiring diagrams, and vendor files are instantly accessible.

- Any team member can see changes, updates, and historical notes directly in the interface.

Everything stays consistent. Everything is anchored to the plant, not buried in a filing system.

eShare works with the formats and systems you already have. It works with your trusted design application and connects your document management system, CMMS and ERP – bringing everything into one unified, visual environment.

This isn’t just a better way to organize documents; it’s a better way to work. It gives technicians clarity, managers confidence, and auditors exactly what they need and when they need it.

As Fortum’s Technical Manager Harri Ranta put it: “When deeper insight is needed, users can seamlessly transition to eShare to locate equipment, check site conditions, and access all relevant documents in one place. This interlinked ecosystem helps us to make faster and more informed decisions.”

Read Fortum’s success story about how they turned scattered information into clarity with digital twin software.

When documentation is no longer a bottleneck, maintenance becomes faster, safer, and more consistent – and that’s something everyone benefits from