Fitjar Mekaniske Verksted – Basic and detail hull and outfitting design

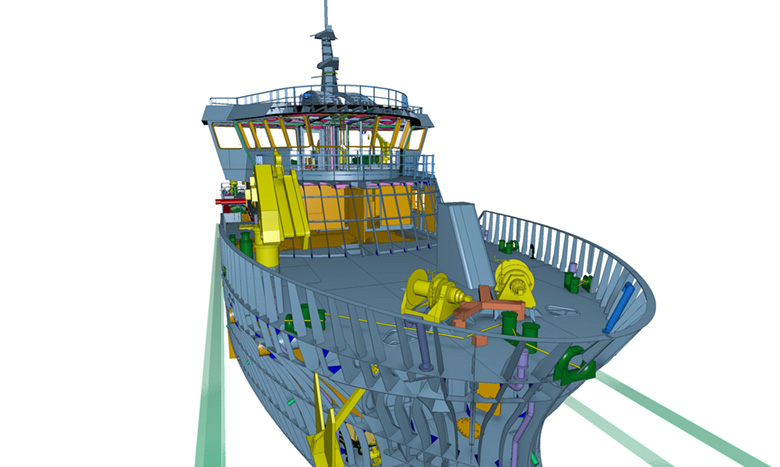

Norwegian shipyard uses Cadmatic for basic and detail hull and outfitting design of fishing vessels, fish carriers, multi-function ships, process ships, and workboats

Fitjar Mekaniske Verksted (FMV) shipyard, located in Fitjar, between Bergen and Stavanger in Norway has been a Cadmatic user since 2014. It has offices in Flekkefjord and Molde and engages in design development, engineering, newbuilds, renovations and ship services. The yard is best known for its newbuilds in the fishing and aquaculture industry, which are built completely in Norway.

“The best features of Cadmatic are the ease with which you can model in tight and complicated spaces and the wide range of autorouting options.”

Robert Blicharski

Engineer

Cadmatic use in a nutshell

Customer challenge

- Create high quality designs with short construction times and high-precision delivery

Cadmatic solution

- Cadmatic has been used since 2014 for all hull and outfitting basic and detailed design

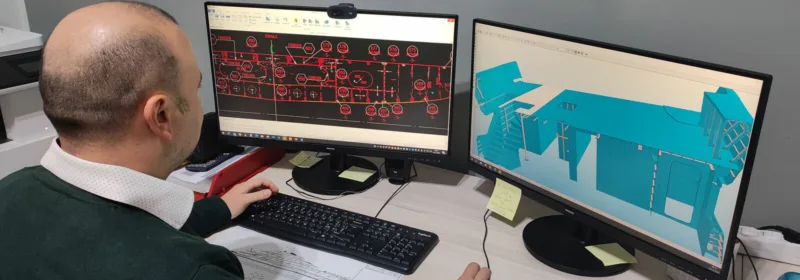

According to Robert Blicharski, Engineer at Fitjar, Cadmatic work sharing capabilities are used to manage design projects between different offices and subcontractors.

“The best features of Cadmatic are the ease with which you can model in tight and complicated spaces and the wide range of autorouting options. We also appreciate the fact that Cadmatic can be integrated with other software, so we can, for example, add a factory that was created in 3D Solid or Inventor to the Cadmatic model,” says Robert.

He has also been impressed with how light Cadmatic models are compared to other 3D design software and how easily CADMATIC eBrowser can be used to show the results of modelling.

“We send eBrowser models to owners and subcontractors This way the owners can continuously control and comment on the design process, if necessary. Our subcontractors also use eBrowser to check the space available for their equipment and for offer calculation and our production uses it to check whether all jobs have been done,” says Robert.

Fitjar projects where Cadmatic was recently used include three process ships, the FMV43 “Taupiri”, the FMV50 “Volt Harvest II” and the FMV53 “Volt Harvest I”. They have also completed a well boat, the FMV44 “Hordagut”, and a multifunctional Norwegian Coast Guard vessel, the FMV47 “OV Hekkingen”