Multi.Engineering – Over 20 years’ design excellence with Cadmatic

Design company uses CADMATIC Laser Scan Modeller in BWTS and SCR retrofit projects

In 2021, MULTI.engineering (Multi) is celebrating its 25th anniversary. It has been a Cadmatic user for over twenty years. The company’s headquarters are located near the banks of the Scheldt river south of Antwerp, close to its roots at the former Boel werf in Temse. Multi’s other offices are located in the Netherlands and Slovakia.

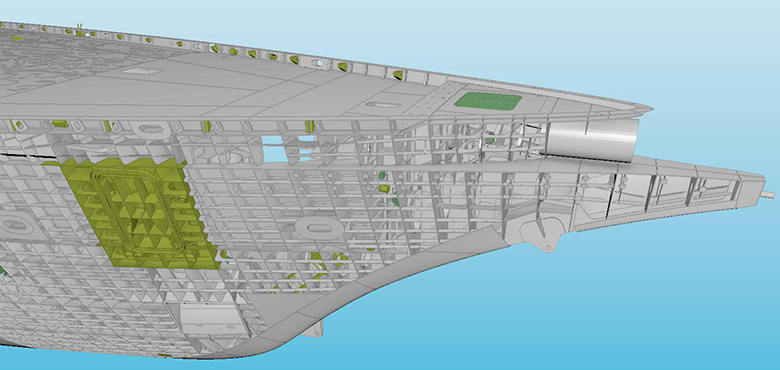

“For newbuilding projects, we use Cadmatic during the basic and detail engineering and allow the client to follow the progress in 3D. With the detail engineering package, we deliver full production packages to the yard for all steel work.”

Dieter Hoeterickx

Design & Engineering Manager (Maritime & Offshore)

Cadmatic use in a nutshell

Customer challenge

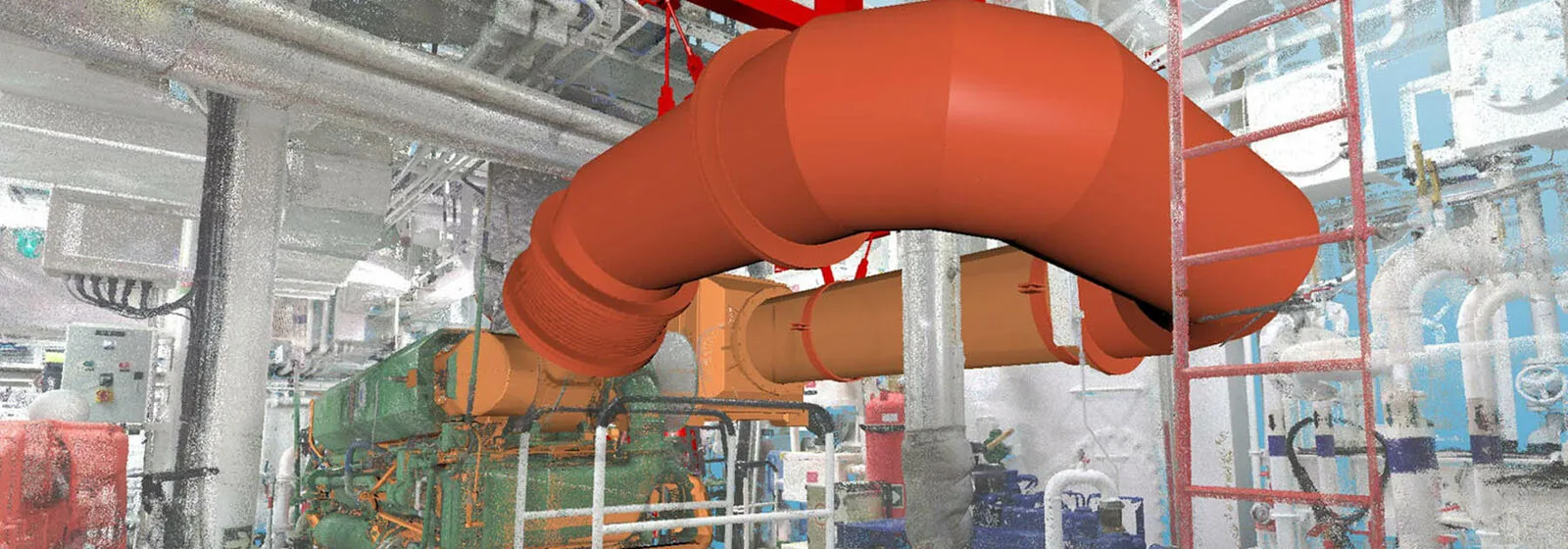

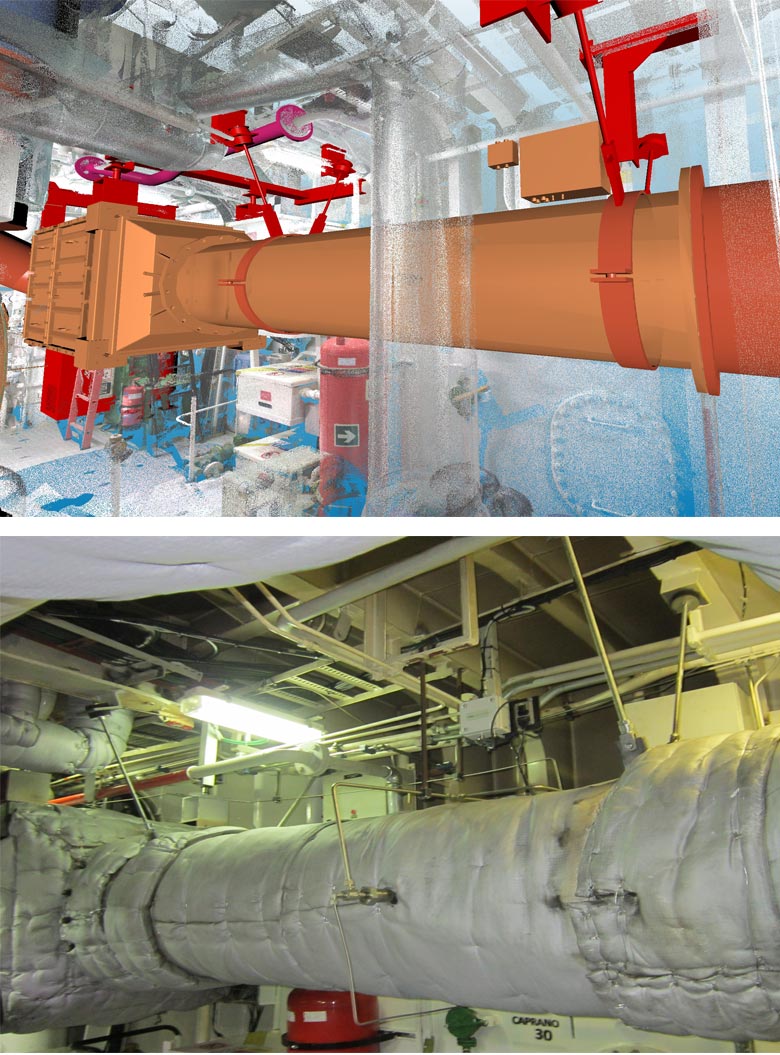

- Combine laser scanned point clouds with 3D models to increase accuracy of 3D modelling in retrofit projects.

Cadmatic solution

- Laser Scan Modeller is used to import point clouds into the Cadmatic models to be used as overlays during engineering in case of construction or for mechanical work to reroute existing piping and new piping.

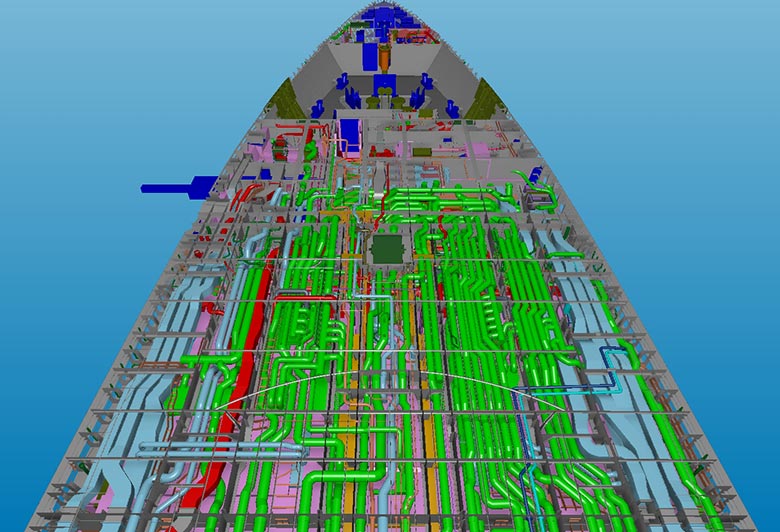

Multi utilizes Cadmatic software mainly for projects in the maritime and offshore sector, but on occasion also for industrial projects. Its services range from concept design up to detail design in terms of engineering, while support is also provided on site by engineers or inspectors during construction and commissioning of maritime assets. In terms of engineering, Multi covers various disciplines such as naval architecture, structural, outfitting and mechanical design in house. For other disciplines, partners are available to ensure that complete support can be offered to Multi’s clients.

“Our clients are active in yacht building, work ships and offshore, both for new construction, maintenance and/or modifications. In addition to the credo “no engineers, no future”, commitment is a very important principle for us, namely a team that is driven to successfully complete projects. That’s what MULTI.engineering is all about, in other words, about involvement,” says Dieter Hoeterickx, Multi Design & Engineering Manager (Maritime & Offshore).

“For newbuilding projects, we use Cadmatic during the basic and detail engineering and allow the client to follow the progress in 3D and also exchange to calculation software. With the detail engineering package, we deliver full production packages to the yard for all steelwork from hull sections to shell plates and loose outfitting. The same applies to all piping work, where we try to use Cadmatic diagram when possible to have a more streamlined detailed engineering process and provide the client with a full production package according to their expectation.”

Refit projects with 3D scans

Multi has started using CADMATIC Laser Scan Modeller for refit projects for basic and detailed engineering of new areas allowing their clients to review progress and shorten the time used for engineering.

It does refits for the installation of BWTS, SCRs, and scrubbers for commercial vessels. In yachting, the refits are more related to extensions of vessels, upgrades of technical spaces, or installations of new helideck/systems, etc.

“We often work with 3D scans in refit projects to use it as an overlay during engineering with the point cloud in case of construction or for mechanical work to reroute existing piping and new piping,” says Dieter.

Electrical module to increase efficiency in mega yacht projects

Dieter says that Multi has also started using CADMATIC Electrical.

“We have done some pilot projects with the electrical module for cable routing on mega yachts to increase the efficiency of the overall engineering process and maximize the use of the Cadmatic 3D model.”

He adds that Multi is currently negotiating with another client to use the Electrical Module in other projects and considering the use of the new tools to create production drawings for rectangular HVAC ducting.