Tekna Shipping takes naval design efficiency to the next level

Italian naval design company achieves 10-15% improvement by streamlining complex naval projects

Tekna Shipping, headquartered in Naples and Genova, Italy, is an expert naval design company. As a strategic partner of Fincantieri and a member of the Delta Naval Engineering consortium, the company is known for its expertise in handling complex hull naval projects in both cruise, military and mega yacht sectors, while consistently embracing innovation and market trends.

“Cadmatic has significantly enhanced our operational efficiency, positively impacting project timelines and team satisfaction.”

Lino Del Gaudio

General Manager

Cadmatic use in a nutshell

Customer challenge

- Manage complex naval projects.

- Detect and correct structural or interface interferences in real-time.

- Facilitate collaboration among departments responsible for naval outfitting.

Cadmatic solution

- Detailed design tools support 3D modeling, 2D drawing, and nesting ensuring adherence to assembly rules.

- Real-time interference detection minimizes errors

- eBrowser and eShare enable rapid sharing and review of 3D models, streamlining project approvals.

Addressing the complexities of naval design

According to Lino Del Gaudio, General Manager at Tekna Shipping, naval design projects come with high demands and levels of complexity.

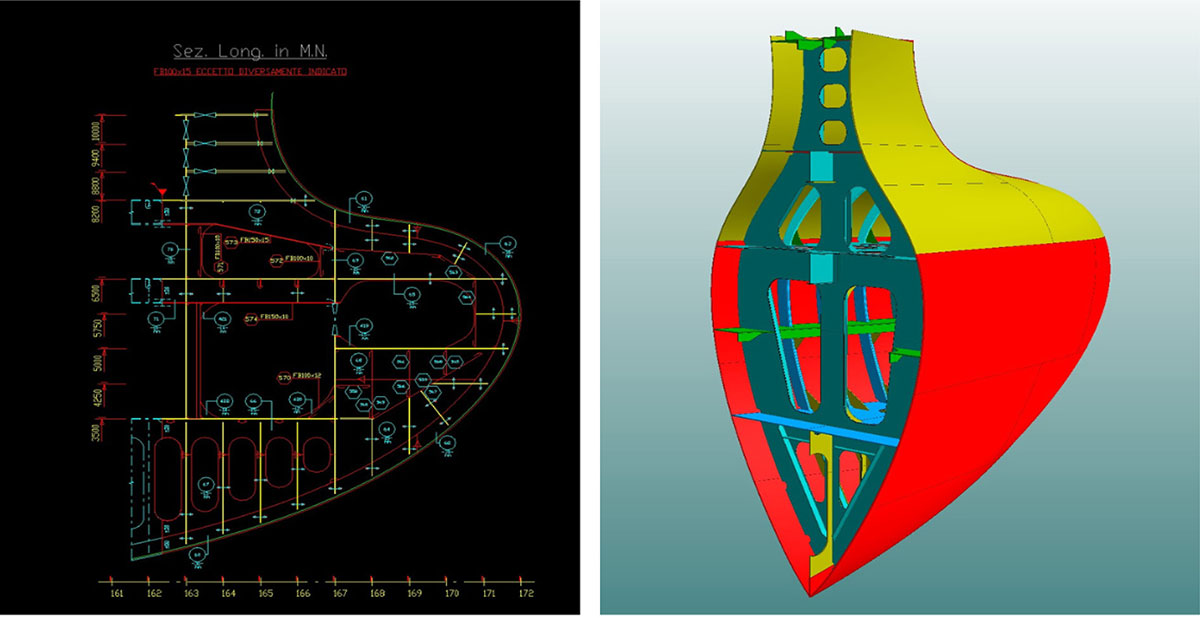

“One of the most significant challenges we face is managing the intricate designs required for naval vessels. These projects demand seamless integration across various stages, from 3D modeling to 2D drawing and the nesting phase of elements. Ensuring compliance with the assembly rules set by construction facilities adds another layer of complexity,” Lino outlines the challenges.

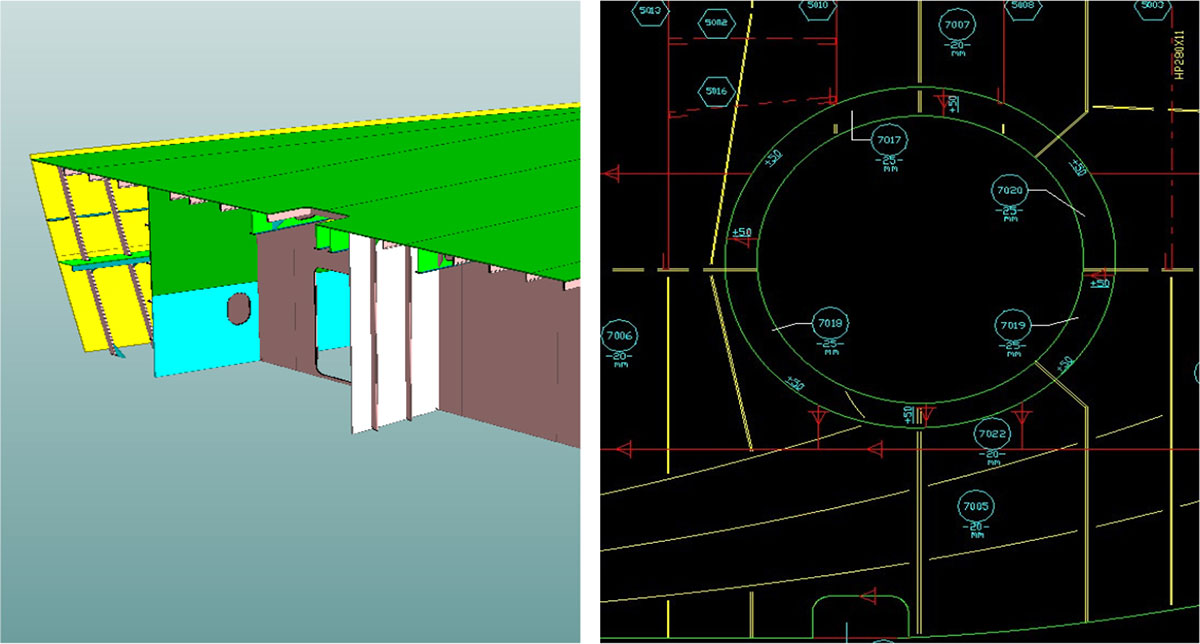

Lino explains that detecting and correcting structural or interface interferences has been a particularly demanding aspect of their work.

“In one recent naval project, we had to ensure that our designs aligned perfectly with the outfitting plans developed by other departments. Without a robust interference detection system, this would have been a time-consuming and error-prone process.”

Streamlining design processes delivers 10-15% improvement

Lino indicates that Cadmatic tools have assisted them in addressing these challenges.

“The software has been a game-changer for us. It’s not just about creating detailed designs; it’s about how seamlessly we can move from one phase to the next. The 3D modeling tools have been particularly valuable, giving us a precise and real-time view of our projects,” Lino shares.

He highlights the value of the software’s real-time interference detection.

“By identifying and correcting structural or interface interferences as they arise, we’ve been able to significantly shorten design timelines. In the naval project I mentioned earlier, this feature alone helped us avoid countless hours of rework and ensured smoother collaboration with other departments resulting in a positive 10-15% improvement.”

Tekna Shipping also leveraged Cadmatic’s eBrowser and eShare tools to facilitate collaboration.

“These tools allow us to share 3D models with our teams quickly. This rapid sharing and review process has streamlined approvals and ensured that everyone stays aligned throughout the project,” Lino explains.

Achieving results and advancing strategic goals

According to Lino, the adoption of Cadmatic has brought measurable benefits to Tekna Shipping.

“Our operational efficiency has improved significantly,” he notes. “We’ve seen noticeable reductions in project timelines, and our teams have expressed high levels of satisfaction with the tools. It’s a win-win situation for both management and our operational departments.”

In the multifunctional naval ship project, Tekna Shipping successfully managed all aspects of the design, from developing the 3D model to producing detailed drawings and workshop documentation.

“This project required us to meet exceptionally high standards. Cadmatic ensured that we could deliver a result that met and even exceeded expectations,” Lino recalls.

Lino emphasizes that Cadmatic has also supported Tekna Shipping’s broader strategic goals.

“By diversifying our client portfolio and increasing the know-how of our resources, we’ve positioned ourselves to embrace new challenges with confidence. Cadmatic has been an essential partner in this journey.”