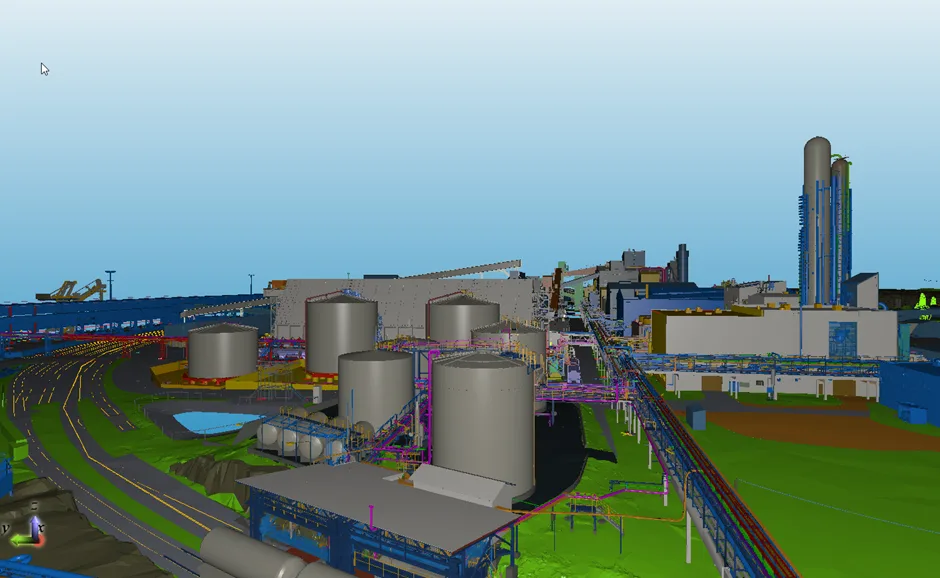

Yara keeps its factory models up to date with Cadmatic

When everyone sees the same digital factory, everything works better.

Factories live and change every day – and Yara Suomi Oy wanted its digital plant model to keep up with that pace.

“Laser scanning gets design moving efficiently and with high quality. eShare ties documents, diagrams, and ERP links into the same view – it helps keep the plant model’s data in good shape.”

Heikki Lehto

Head of Projects

Cadmatic use in a nutshell

Challenge

- Need to ensure the reliability of spatial data. Old geometry or geometry imported from other systems did not always match the real situation.

- External design work is difficult unless it is done in real time in a shared environment.

- Incomplete information content: not all areas had complete attribute data (“a smart model”), which limited analytics and integrations. Enriching and “smartening” the attribute data is still ongoing continuously.

Solution

- Elomatic’s 3D scans: Laser scans carried out several times a year produce accurate point-cloud data, from which a surface model is created and connected directly to Yara’s main plant model.

- eShare and eBrowser

- Links documents, P&ID diagrams, and ERP data directly to 3D objects.

- Enables checking diagrams against the model and spotting inconsistencies.

- Opens and uses the same model with CADMATIC eBrowser, which is used alongside eShare for lighter-weight needs.

- Cadmatic’s support and training: Implementation went smoothly, and continuous support is available.

Yara has used Cadmatic software in plant design for over 20 years. Today, the company maintains a single comprehensive 3D plant model in the CADMATIC 3D Plant Design system – a living digital version of the plant that connects different departments and functions.

To ensure the model remains accurate and up to date, Yara uses Elomatic’s laser scanning and CADMATIC eShare’s intelligent information management.

eShare works as a digital information platform that links the 3D model to documents, diagrams, and ERP data – keeping the information needed by design, maintenance, and production in the same reality

Together, these solutions make it possible for the entire organization to use the same, up-to-date information from one place, saving time and improving the quality of decision-making.

From scan to living model

Laser scanning is carried out a few times a year at Yara’s plant in Uusikaupunki. In a couple of days, Elomatic’s experts capture accurate point-cloud datasets that reflect the plant’s real current state.

The surface model produced from the scans is connected directly to Yara’s main plant model – creating a continuously updating digital twin that lives alongside the plant. All changes and additions are stored in one shared model. The model is therefore no longer just an archive – it is a living tool used daily in design, maintenance, and production.

“When the same people come to do the scans, they know the site and the practices – that speeds up the work and ensures quality.” says Lehto.

Information flows seamlessly

When Yara introduced eShare, the goal wasn’t only to visualize data – but to connect it. eShare turned the 3D model into a digital information platform for the whole plant, where documents, diagrams, and ERP links sit in the same view.

Now designers can verify the consistency of diagrams and the model directly in eShare, maintenance and other users find up-to-date information quickly, and project managers can see at a glance what has been updated.

All work is based on the same reality – and everyone sees the same plant.

Achieved results and next steps

At Yara’s plant, information management is now clearer, faster, and more reliable than ever. Thanks to eShare, Elomatic’s scans, and other partners maintaining the model, Yara manages its entire plant through one model – one source of truth.

The accuracy of spatial data has reduced the need for repeated measurements.

eShare’s linking encourages keeping data and attributes in good order, which shows up as better information quality and more efficient work across departments using the model.

“Checking diagrams against the model works extremely well in eShare – this feature is missing from eBrowser.”

Next, Yara will focus on continuing to “smarten” the model – meaning completing attribute data across the entire plant model. When all objects in the model contain data, a Tag, or another ID which, through system integrations, provides access to plant data and information sources, the model’s potential grows even further.

The company will keep developing the design environment together with Cadmatic and other partners maintaining the model to ensure version upgrades and development continue smoothly.

The result is a plant that lives in time – and a digital model that keeps up with it.