Create a dynamic digital twin for shipbuilding and process industries

Overview of industrial digital twins

Project data is often scattered across models, documents, systems, and teams, making it hard to see the full picture and avoid costly mistakes.

A digital twin brings everything together. It is a virtual replica of your physical asset, updated with real-time data from 3D models, P&IDs, databases, and performance metrics.

Whether you’re optimizing construction, design reviews, or operations, it becomes your single source of truth. Start making better decisions with one smart digital twin.

Industrial digital twin

-

Clarity to count on

When all your design, documentation, and data live in one intuitive hub, you’re not just better informed. You’re empowered to take control, stay ahead, and drive progress. -

Everyone in sync

Keep everyone on the same page, wherever they are. Real-time access to synchronized data means fewer misunderstandings, smoother teamwork, and decisions you can trust. -

Speed it up

Get up and running in days, not months. No 3D model? No problem. With fast-track digital twin creation, you spend less time setting up and more time making an impact.

Features of Cadmatic’s digital twin

-

Digital twin for shipbuilding and offshore structures

Complex ships and offshore structures demand advanced solutions. A digital twin ensures that design, PLM, ERP, and MES data is seamlessly connected across the entire project. Whether for shipyards, classification societies, or shipowners, the platform supports operations from engineering to maintenance.- Integrated data environment for stakeholders: Digital twins unify design, engineering, and operational data to ensure consistent and real-time access across the project lifecycle.

- Virtual validation of ship systems: Simulation and clash detection in the 3D model allow early identification of design issues before construction begins.

- Real-time operational insights and analytics: Live data from onboard systems enables performance monitoring, predictive maintenance, and informed decision-making.

- Digital continuity for regulatory and lifecycle management: A digital twin provides a traceable audit trail from design to operation, supporting compliance and asset lifecycle control.

-

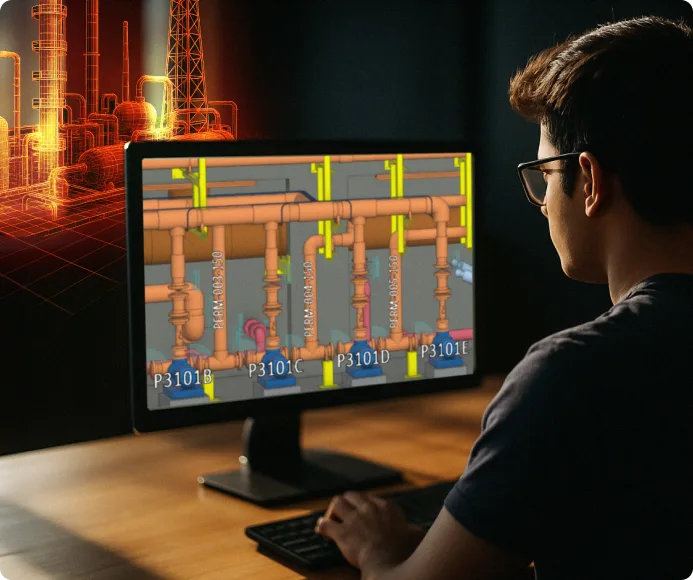

Process industry digital twins

In the process industry, a digital twin goes beyond a static 3D model; it’s a dynamic, evolving digital entity integrated with real-time process data, supporting everything from construction site management to operations and maintenance.- Smooth data integration: Merge 3D models from multiple CAD formats and connect live data.

- Advanced visualization: Interact with project data in a powerful 3D web-based interface.

- Full lifecycle support: From design to construction and operational maintenance.

- Proactive issue resolution: Detect and address problems before they disrupt your schedule.

“When you visualize data in a realistic digital image of the plant, it dramatically improves the quality of information conveyed to the user. It gives the site management a much greater amount of information in a single screenshot. This assists the site management to take more effective operational decisions.”

Frequently asked questions about digital twins

What is a digital twin and how does it apply to ships or industrial plants?

A digital twin is a dynamic digital representation of a physical asset that brings engineering and operational information into one structured view. For ships and industrial plants, it links 3D models, P&IDs, documents, tags, and system data so teams can find trusted context fast. Selecting a piece of equipment can reveal drawings, manuals, maintenance history, and status from connected systems. During projects, it supports design reviews, change control, and handover. In operations, it helps troubleshooting, inspection planning, and modifications by keeping asset information accessible, current, and aligned across stakeholders.

How does a digital twin work?

A digital twin works by connecting an asset’s information into one structured view that people can use across the lifecycle. It starts with a backbone of assets, tags, and relationships. On top of that, it links engineering content like 3D models, P&IDs, drawings, and documents, so selecting an object reveals the right related information. The digital twin gains more value when it also connects operational and maintenance data from business systems, such as inspection records, work orders, or performance metrics. The key is ongoing updates. A useful twin stays current through clear change workflows and traceability, so teams see what changed, when it changed, and what it impacts.

How does a digital twin differ from a traditional 3D model or P&ID?

A traditional 3D model or P&ID is usually a design snapshot. It may be accurate for its purpose, but it often lives in a design tool and does not stay connected to lifecycle information. A digital twin links models and diagrams to documentation, asset data, and system connections, so the same object can carry identity, history, and status. That makes it usable beyond design, for handover, maintenance, inspections, and modifications. “Live” can mean updated documents, change traceability, and data feeds from business or operational systems, depending on scope and maturity.

What different types and levels of digital twins are there?

Digital twins are often described by maturity level, based on what they help you do. A descriptive twin focuses on visibility: a structured asset view with 3D, P&IDs, and linked documents so teams can find information fast. A diagnostic twin adds status, history, and context to support investigation and root-cause work. A predictive twin uses operational and condition data to forecast issues and performance changes. A prescriptive twin supports recommended actions, workflows, or rule-based guidance, sometimes connected to automation. Many industrial programs start descriptive, then expand toward diagnostic and predictive as data quality improves and integrations mature across engineering, operations, and maintenance.

What are the main benefits of using a digital twin in marine or process operations?

Key benefits include faster troubleshooting and fewer delays because teams can access the right information in context, without hunting across systems. A shared view supports safer work by improving planning, isolations, and decision-making with clearer asset understanding. Remote collaboration improves because stakeholders can review the same up-to-date information, even without CAD tools. Training benefits from a visual, structured asset view that reflects how the ship or plant is organized. Digital twins also support compliance by improving traceability and documentation control, and they help sustainability goals by reducing rework, improving maintenance planning, and supporting performance visibility where data is available.

Do I need an existing 3D model to get started with a digital twin?

Not necessarily. Many organizations start a digital twin from existing P&IDs, equipment lists, tag registers, and documents, then connect and structure that information so it is usable day to day. A 3D model improves visual understanding and navigation, but it can be added later as the twin matures. If needed, 3D content can be created or updated using laser scanning or photogrammetry to reflect the current state of the ship or plant. Starting without 3D lets teams deliver early value through better information access, clearer context, and faster collaboration while building toward richer visual detail.

What are the challenges of building digital twins?

Industrial digital twins can be hard to build because the starting data is rarely clean or complete. Asset information often sits across P&IDs, 3D models, drawings, spreadsheets, and maintenance systems, with inconsistent tags and missing links. Many sites do not have an up-to-date 3D model, so teams must combine documentation, scans, and field knowledge to create a trustworthy baseline. Integration can also grow quickly, because each connected system adds data mapping, access control, and governance needs. The biggest long-term challenge is keeping the twin current. If change updates do not flow back into the twin, value drops fast and trust is lost.

How long does it take to set up a digital twin?

Setup time depends on the starting point and the outcome you want first. A basic digital twin focused on consolidating and linking documents, tag data, and existing models can be operational in a few days to two weeks. More comprehensive setups typically take four to eight weeks when they include data cleansing, structured asset relationships, access control, and integrations to systems such as maintenance, inspection, or operational data sources. The biggest timeline drivers are data quality, how many sources must be connected, and how change workflows will be handled so the twin stays current after go-live.

What is the digital twin market, industries and applications?

Digital twins are used across industries that manage complex, long-life assets and need better control of engineering and operational data. In shipbuilding and offshore projects, twins support design reviews, production planning, change control, and lifecycle handover. In process industries such as power, oil and gas, chemicals, and other plants, twins help teams manage documentation, maintenance planning, inspections, and modifications. Common applications include asset information management, progress and status visibility, and faster troubleshooting with the right context. As organizations connect more systems and sensor data, twins also support performance monitoring and predictive maintenance. Growth is driven by the need to reduce rework, improve safety, and keep stakeholders in sync.