SEFT Engineering takes inter-disciplinary design efficiency to next level with Cadmatic

Turkish engineering & consulting company selects Cadmatic to take advantage of advanced 3D modeling, simulation, and integrated design capabilities.

SEFT Ship Design (SEFT) offers engineering and consulting services internationally in maritime & shipbuilding, industrial construction, defense industry, and power generation projects. In ship design, the company’s services range from concept design, feasibility studies, and detailed design all the way to technical consultancy.

The company has made a name for itself for its innovative solutions and use of advanced technologies. SEFT has set its sights on incorporating next-generation technologies such as digital twins into its projects to provide smarter and more efficient solutions to its customers. Cadmatic has become one of the cornerstones of the pioneering company’s advanced technology stack.

“Cadmatic has helped us to improve the quality of our projects, reduce costs, and shorten delivery times.”

Cenker Çoban

Business Development Director

Cadmatic use in a nutshell

Customer challenge

- Manage clash-free integration of all systems in multi-disciplinary design from concept to delivery.

- Manage complex piping systems, integrate electrical systems, and accelerate 3D modeling process for demanding LNG Carrier design.

Cadmatic solution

- Cadmatic’s efficient integrated engineering and design software solutions provide common language for inter-disciplinary collaboration.

- Cadmatic’s advanced 3D modeling and simulation capabilities, user-friendliness and extensive database allow efficient design and minimization of errors during LNG project.

Getting stronger with Cadmatic

In October 2022, SEFT decided to enhance their ship design capabilities by selecting Cadmatic as an additional software solution for their new ship design projects. According to Business Development Director Cenker ÇOBAN, key reasons for the decision were Cadmatic’s advanced 3D modeling and simulation capabilities as well as its user friendliness.

“We chose Cadmatic as we saw that its advanced 3D modeling and simulation capabilities could significantly enhance the accuracy and efficiency of our projects. The user-friendly interface also allows our teams to work quickly and effectively,” says Cenker.

He adds that the integrated solution offered by Cadmatic facilitates collaboration and data exchange between different engineering disciplines, ensuring smoother and more coordinated project progress.

“The specific advantages of Cadmatic include the ability to quickly model and manage design changes, a comprehensive library of parts and components, highly accurate analysis and simulation tools, and the capacity to integrate with other engineering software solutions. This improves the quality of our projects, reduces costs, and shortens delivery times.”

Cenker is appreciative of the support that local Cadmatic reseller Arti Engineering provided during the transition and training process.

“Arti Engineering was very attentive, and we learned a lot during the training sessions. They have also supported us during the implementation and use of the software.”

Challenging LNG carrier design project

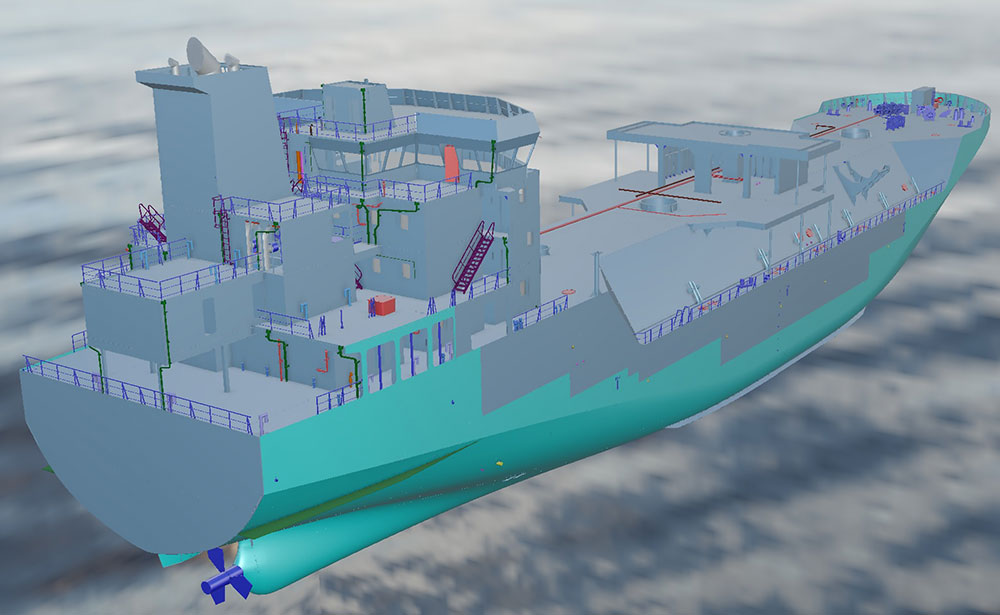

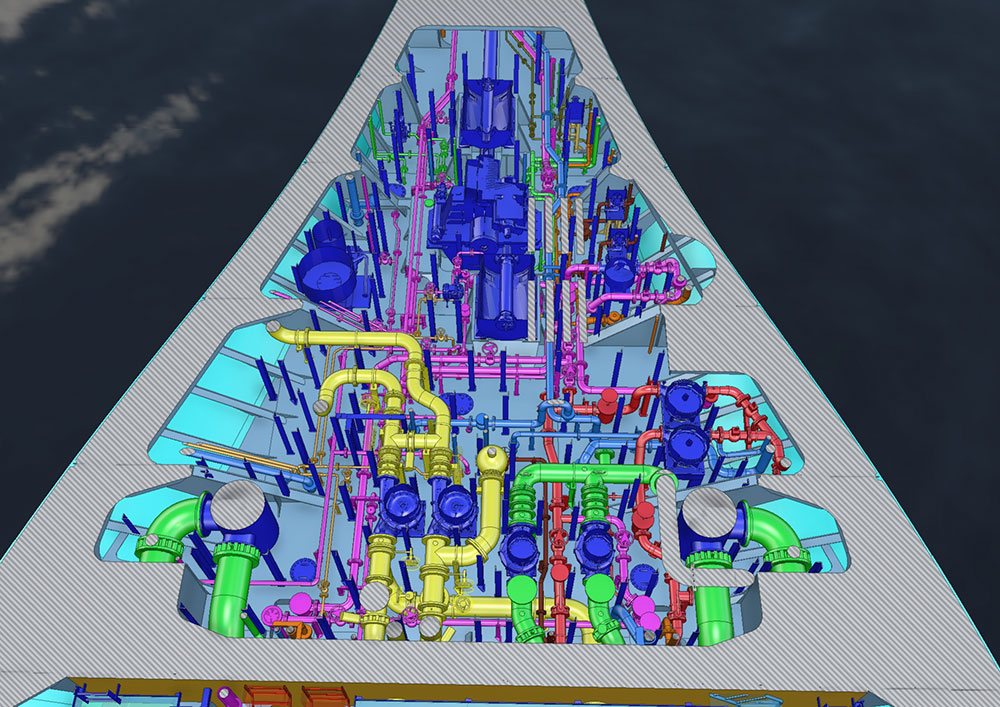

SEFT are currently using Cadmatic in several projects, a notable example is the design and construction of a LNG Carrier Vessel.

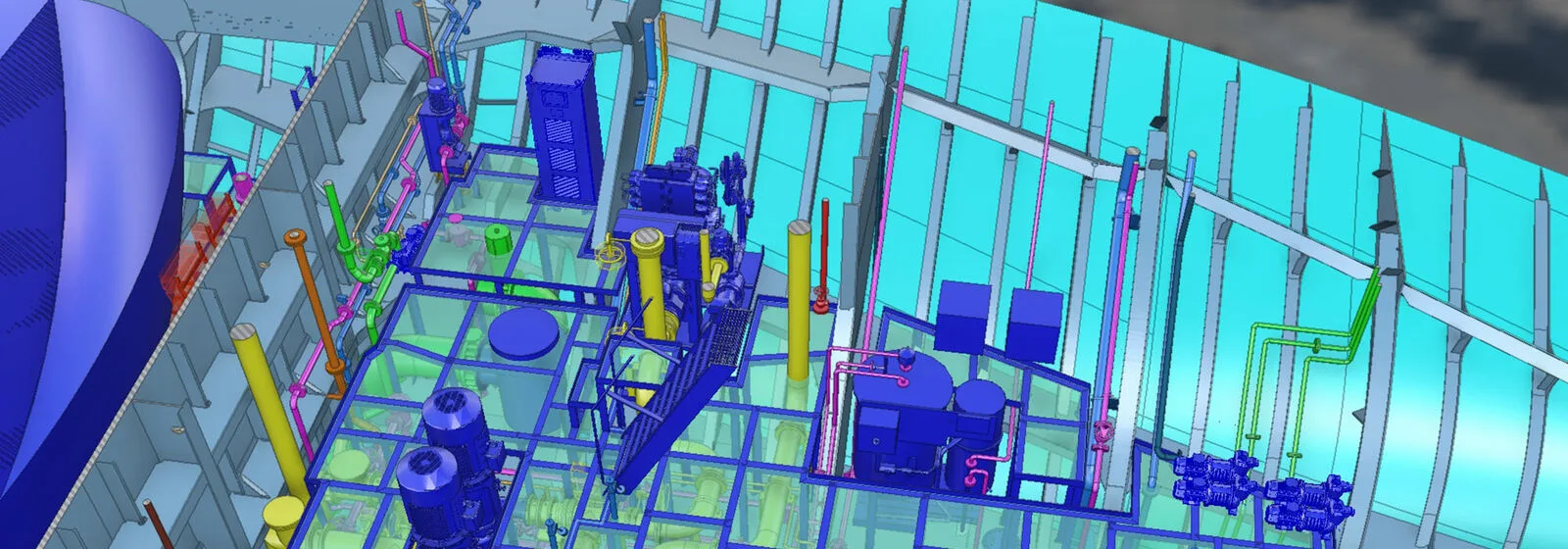

The LNG carrier project is challenging due to the need to manage complex piping systems, integrating electrical systems, and accelerating the 3D modeling process.

“Cadmatic has helped us overcome these challenges with its advanced 3D modeling and simulation capabilities. The software’s user-friendly interface and extensive database have allowed our engineering team to work more efficiently and minimize errors during the design process of the LNG carrier,” says Cenker.

Integrated solution driving collaboration

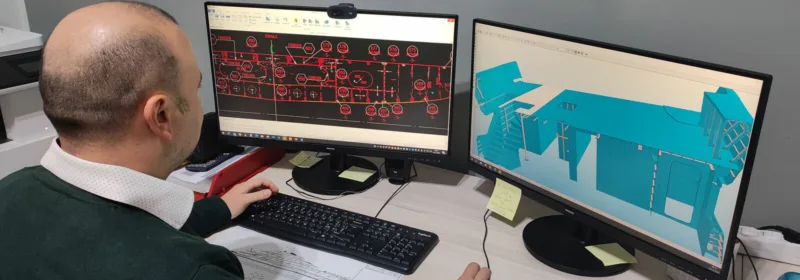

The integrated Cadmatic solution is highly appreciated by SEFT employees as it has facilitated collaboration between their different engineering disciplines, for example, construction and outfitting departments.

The successful implementation and benefits gained have provided SEFT with the motivation to expand the use of Cadmatic.

“In the future, we plan to expand the use of Cadmatic even further. We aim to utilize it more intensively in our commercial and military projects as well as our powership projects,” Cenker outlines SEFT’s future plans.