Making plant maintenance specialists’ lives easier – and delivering real ROI with CADMATIC eShare

Ask any plant worker what slows them down, and you’ll hear a familiar story:

“It’s not the work itself. It’s finding the right information to do it.”

In complex facilities, maintenance teams often juggle multiple systems – work orders in Maintenance Management System (CMMS), drawings in engineering databases, instructions in document management systems (DMS), and notes buried in email threads. Studies show that up to 40% of maintenance time can be lost just searching for information.

That’s not inefficiency, that’s opportunity.

Uniting your tools into one smart view

Digital transformation has brought incredible tools to maintenance, predictive analytics, AI, mobile apps , but it has also added complexity. What workers need isn’t more systems. It’s a way to bring those systems together.

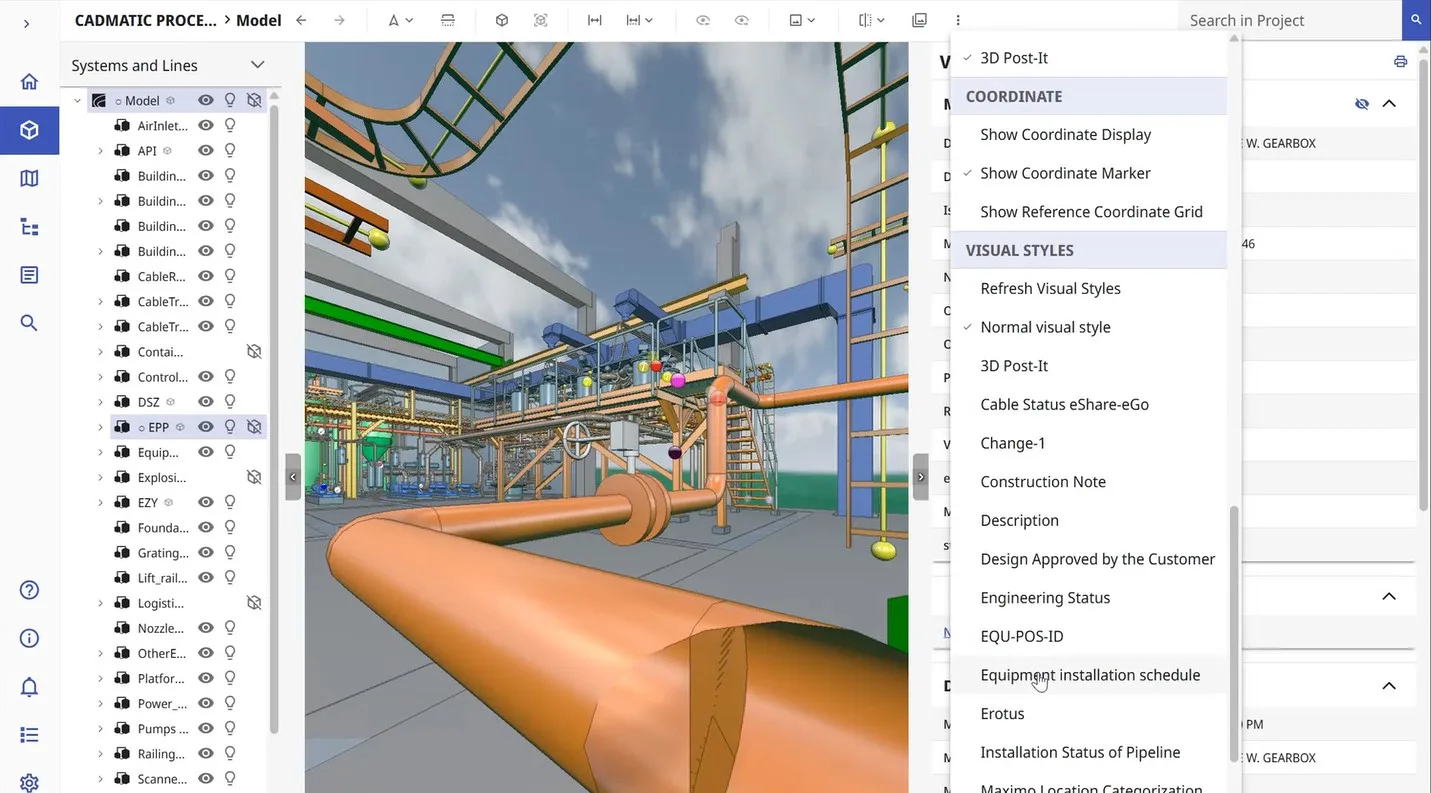

That’s where CADMATIC eShare comes in: a unifying platform that connects all maintenance related information and systems and presents it in an easy, visual way. Whether you’re a planner, technician, or manager, eShare helps you see everything that matters; and nothing that doesn’t.

See the whole story behind every task

Integrated with CMMS eShare enriches every work order with relevant information in visual context. With a single click or by scanning a QR code, you can open the location of an asset in a Digital twin and see all the task related information. No more guessing, no more searching.

Need to repair a pump?

Instanly access the equipment location, LOTO procedures, manuals etc. To proceed safely with confidence. On a mobile device, even without network connection.

It’s maintenance made mobile – and made easy.

Empowering every role

- Planners can see the full picture before assigning tasks, spotting risks early

- Technicians get clear visual guidance on what to do and where to go.

- Operators can access key maintenance data without needing CMMS expertise.

- Subcontractors can orient themselves quickly, even before arriving on-site.

It’s the kind of simplicity modern workers expect; intuitive, mobile, and visual.

The results: Time saved, downtime reduced

When you reduce time spent searching for information from 40% to even 10%, the numbers speak for themselves. That means hours reclaimed every day – and massive reductions in downtime risk.

A single hour of production downtime can cost €100,000 or more. eShare helps prevent those moments by enabling faster responses, better coordination, and more confident decision-making.

And the return on investment? It’s not just financial. It’s human.

When workers feel equipped, informed, and empowered, their focus shifts from finding information to using it.

Making maintenance easier isn’t about adding more tech – it’s about connecting what you already have.

With eShare, plant workers finally get a tool that helps them focus on what really matters: safe, efficient, and confident maintenance.