Agentic shipbuilding 101 – What AI agents really mean for ship design

If you work in ship design or production, you’re probably hearing a lot about artificial intelligence right now. Some of it is exciting, some of it is hype, and some of it may feel very far removed from the day-to‑day reality of getting steel drawings, production data‑ and class packages out the door.

At Cadmatic, we’ve been asking a simple question: What would AI have to do to be genuinely useful to a ship designer or shipyard engineer?

The answer we’re working on is something we call agentic shipbuilding – a way of using AI “agents” to automate multi‑step tasks, keep data flowing between systems, and propose design options, while engineers stay firmly in control.

This article explains what that means in practice, in plain language.

Why ship design needs new kinds of digital help

Modern vessels are getting more complex with new fuels and energy systems, tighter environmental and safety rules, and more stakeholders and data sources than ever before.

At the same time, many design offices still depend on a mix of 2D and 3D tools, Excel sheets and custom scripts scattered across the company, and a few “wizards” who know how to drive APIs and internal libraries.

That creates bottlenecks. When your best people are spending hours writing small scripts, hunting through documentation or translating specifications into CAD steps, they’re not doing what they’re best at, which is making good engineering decisions.

This is exactly the kind of problem AI agents are good at tackling.

What is an AI agent?

Forget the buzzwords for a moment. In our context, an AI agent is simply a piece of software that can:

- Understand a task you describe in natural language (“Create a bracket type for this geometry”, “Find all ABB motors at 230V”, “Show me outstanding tasks for this block”).

- Plan the steps needed to complete that task using the tools it has access to (APIs, databases, models).

- Execute those steps, calling Cadmatic applications and other systems on your behalf.

- Report back with results you can review, adjust, and approve.

One nice way to think about it is that AI agents know the APIs so that you don’t have to.

Instead of learning every scripting interface or integration detail yourself, you tell the agent what outcome you want and supervise what it does.

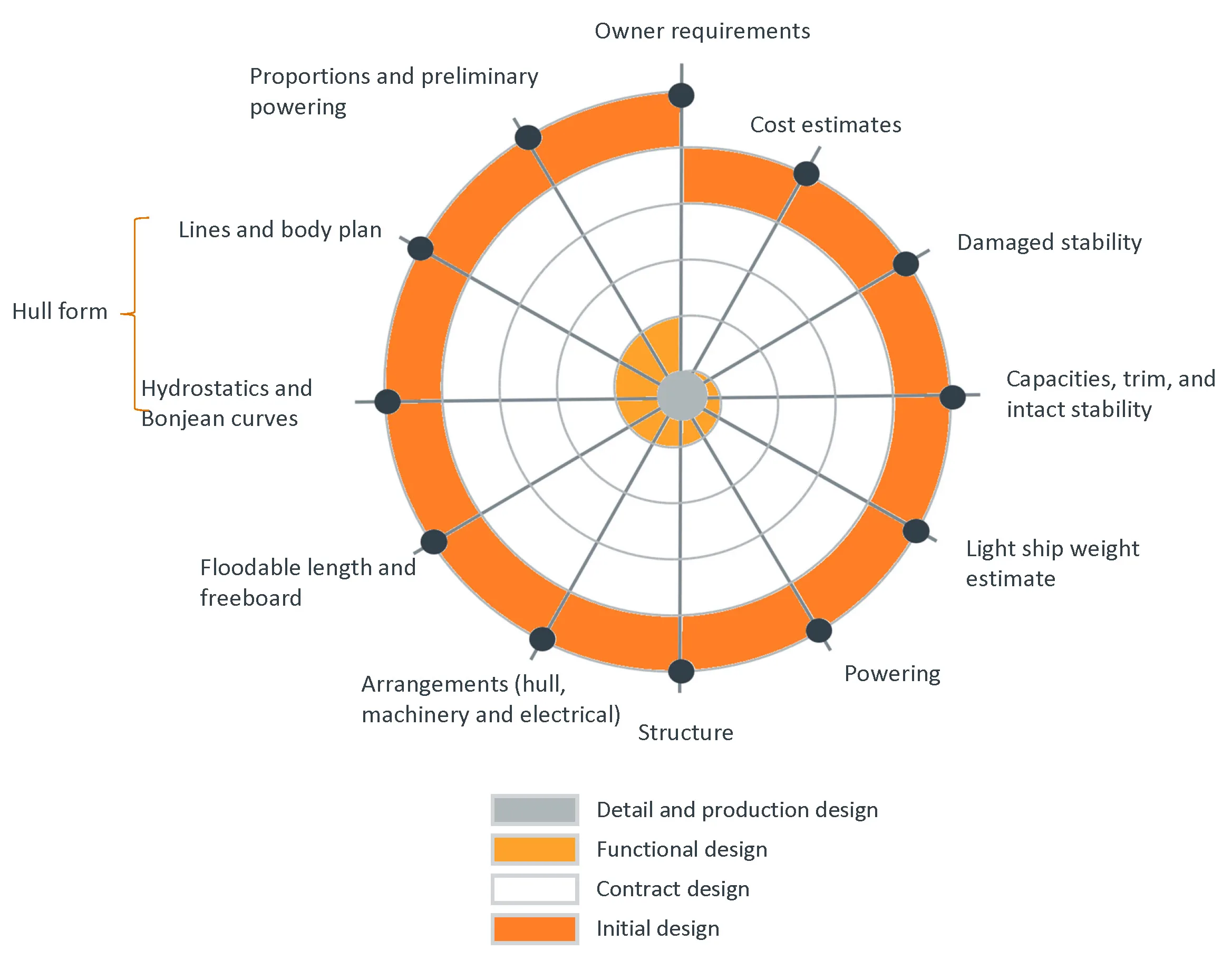

From the design spiral to agentic workflows

Naval architects often talk about the design spiral. It is the iterative loop from initial concept through basic, functional, and production design. In reality, these stages overlap heavily. Construction often starts before the design is “finished”, and each change can spread through drawings, models, materials and schedules.

Agentic AI doesn’t replace the spiral. Instead, it helps you move around it faster and with fewer manual hand‑offs.

Figure 2. Ship design phases adapted from Evan’s design spiral

In our research and early prototypes, we focus on three broad roles for AI agents:

- Digital co‑pilot – helping with scripting, macros and repetitive CAD operations.

- Workflow automator – carrying out multi‑step tasks like library creation, data conversion or data retrieval across systems.

- Design recommender – suggesting options based on rules, standards and past projects, which engineers can accept, adapt or reject.

In the following section, we make that more concrete.

Four ways Cadmatic is using agentic AI

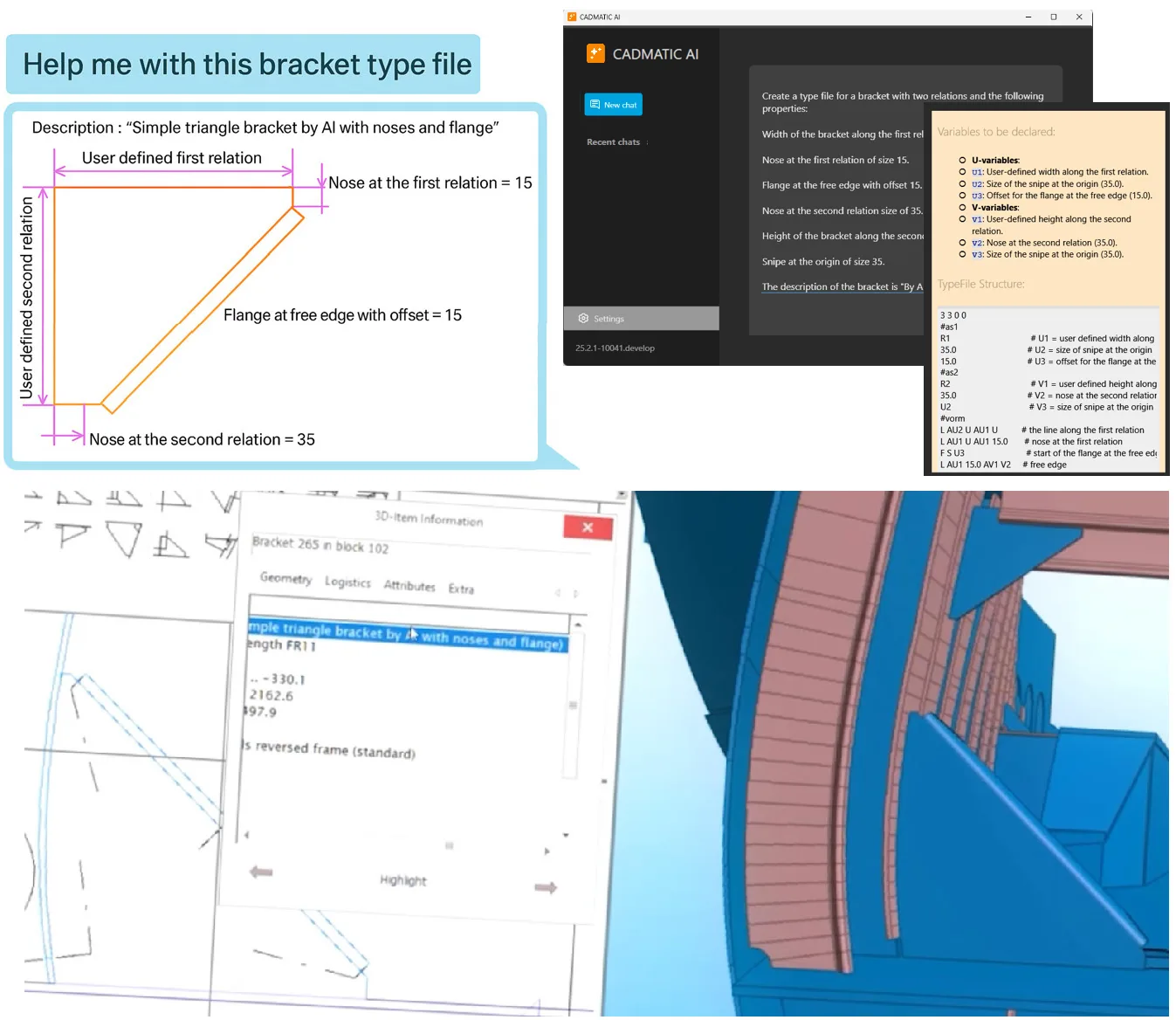

1. Automating the boring bits: bracket libraries

Library creation and maintenance is a classic hidden bottleneck. Creating and updating bracket types, for example, often means writing proprietary scripts that only a few specialists understand.

With our bracket agent, you can sketch or annotate the bracket you need – or simply reference an existing one. Describe the requirements in natural language, such as nose length, flange sizes, or applicable standards. The agent then automatically generates the script, ready for you to review and save to your library.

In internal tests and demos, this approach can cut the time needed to create and update bracket types by up to around 75%. The engineer’s role shifts from “coding and debugging” to “specifying and supervising”.

Figure 3. AI-generated bracket type in CADMATIC Hull

2. From textual specs to structured data

Another area we’re exploring is turning unstructured requirements into structured models. For example, an agent can read owner requirements, rule summaries, and specifications from previous projects. It extracts key parameters and builds a structured description that can be used to generate models or standard exchange formats like OCX. From there, it can call Cadmatic APIs to create a basic 3D model, which you can then refine further.

You stay in control of the design. The agent just removes the hours of manual translation from text to CAD operations.

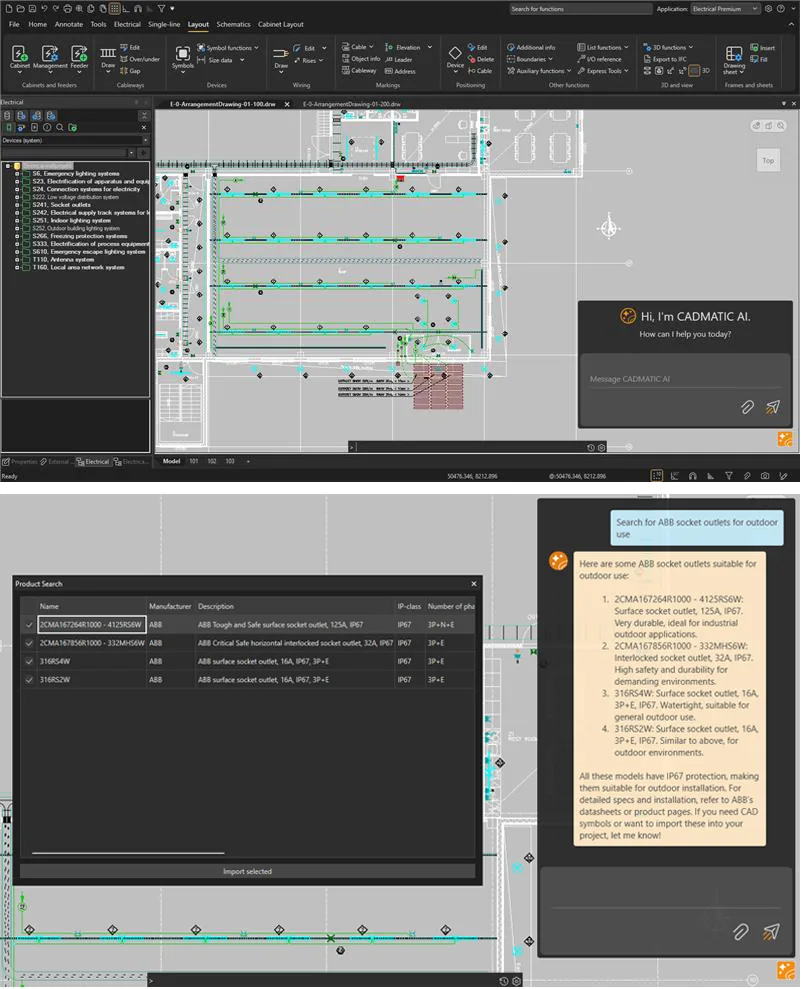

3. Keeping electrical equipment data accurate and consistent

Electrical equipment varies widely between suppliers, and naming, pricing, and product lines change constantly. Today, maintaining accurate electrical catalogs often means manual updates or scattered spreadsheets, which leads to inconsistencies, outdated data, and extra rework.

Our electrical AI agent is designed to solve this by building and maintaining an up-to-date equipment database automatically. Engineers can simply describe what they need – for example, “show me ABB motors at 230 V” – and the agent searches trusted sources, extracts the relevant information, and converts it into Cadmatic’s electrical data structure. Beyond updating catalogs, the agent can also modify selected items directly in the model, replacing outdated components with imported ones under user supervision.

The result is cleaner data, less manual catalog maintenance, and faster, more accurate model updates. Engineers spend less time on repetitive tasks and more time designing safe, reliable electrical systems.

Figure 4. Product model creation with AI in CADMATIC Electrical

4. Data-driven collaboration

A typical shipbuilding project generates an enormous amount of data across models, documents, PLM, and other systems. Finding “the one thing you need right now” can be painful.

Our data-driven collaboration agents are being designed to work seamlessly within environments like CADMATIC eShare and CADMATIC Wave. In the future, they will support practical queries such as “Which welds in this block still lack inspection reports?” – helping teams get answers faster and with less friction. They can gather information from multiple systems – including models, PLM platforms, and documents – and bring everything together in one customized view. The results can be fed back into your existing collaboration tools, like Microsoft Teams, so you don’t need to switch between windows to stay on top of your tasks.

The aim is not to create a talking chatbot for its own sake, but to shorten the distance between a question and an answer.

What Agentic AI is not

It’s important to be clear about what we are not trying to do.

AI agents are not a replacement for naval architects, structural designers, or planners. They do not make final decisions about safety, class compliance, or cost. They do take over repetitive, rule-based tasks and give engineers better information faster.

Our vision is simple: Let humans do the creative, judgement-heavy work; let AI agents handle the grind.