Making PLM practical for shipbuilders

Product lifecycle management (PLM) is not new, but in shipbuilding it has often been seen as too complex and slow to implement. Others have argued that it is too disconnected from everyday design and production work to be practical in shipbuilding. Many shipyards have, nevertheless, tried generic PLM solutions, only to find that they failed to fit the unique needs of shipbuilding projects.

There is, though, a different approach that can deliver the desired results. Rather than forcing shipyards to adapt to generic PLM processes, we have to deliver shipbuilding-specific tools and data connections that make PLM simple, flexible, and ready for shipbuilding from day one.

Cadmatic’s digital twin software CADMATIC eShare is an example of a tool that can build such a bridge to comprehensive PLM in shipbuilding. It allows shipyards to begin by improving data access, visualization, and communication today, and expand into full PLM workflows when greater control, quality, and traceability are needed. It can be used as a stand-alone collaboration tool or as part of a PLM solution like CADMATIC Wave. By providing ready-made shipbuilding data models, integrations, and templates, Cadmatic removes much of the complexity that has held PLM back in the industry.

Features that solve real problems

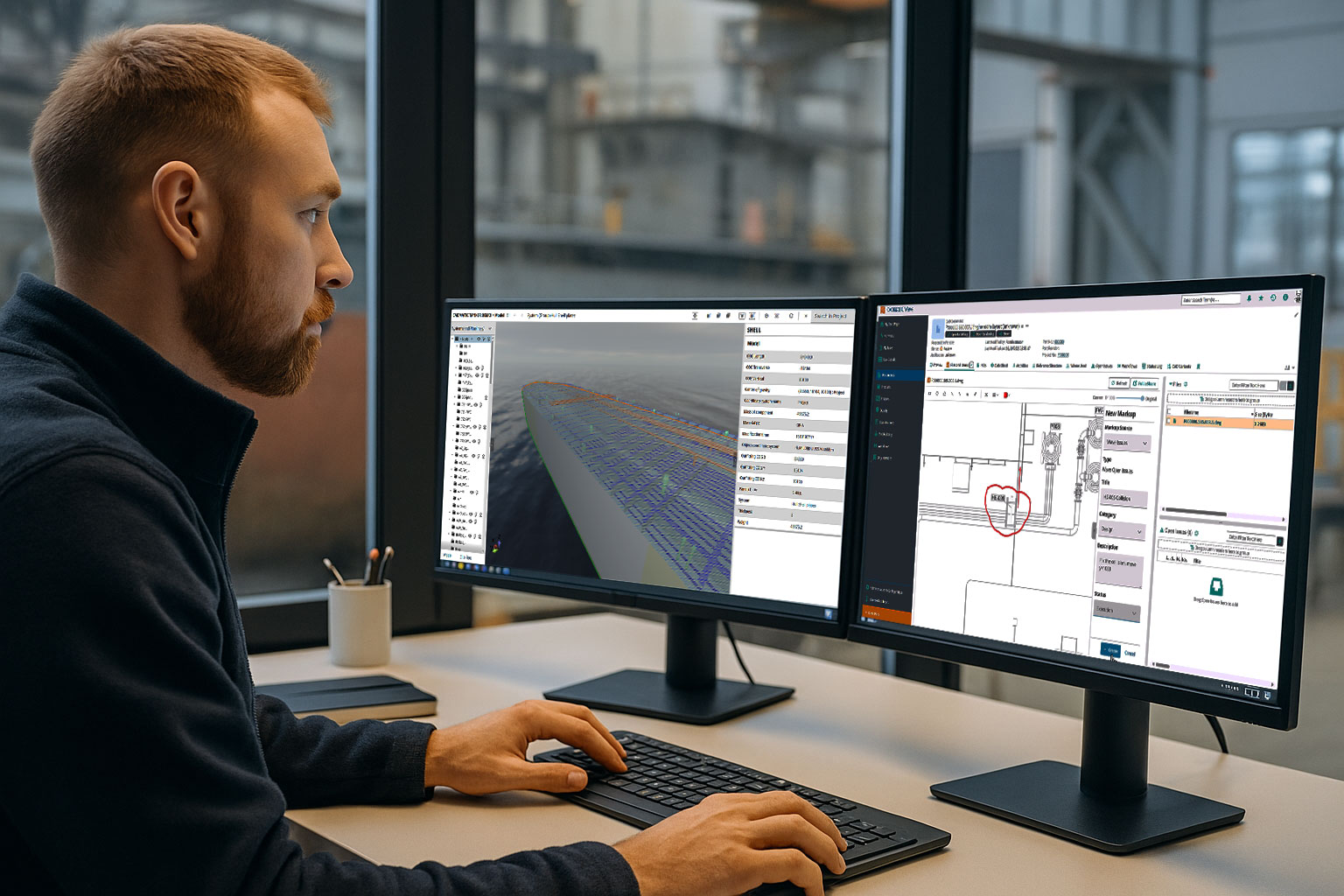

Recent updates make eShare more powerful and easier to adopt. Document markups allow teams to collaborate directly on drawings, linking comments and issues to both 2D and 3D objects. Collision checking improvements give clear, shareable reports that help prevent costly mistakes. The customizable home view and advanced search tables turn project data into practical dashboards, while laser scanning integration and 4D animations bring the physical and digital worlds closer together.

eShare connects naturally to CAD models, ERP and PLM data, and even laser scans. It can run on the cloud, on-premise, or in hybrid setups, and it supports tablets and offline tools like CADMATIC Ego for use in shipyards. This flexibility means that even the largest projects like cruise ships can be accessed in a browser without complicated setups.

A simpler way to achieve PLM value

Many PLM initiatives fail because they try to do too much at once. eShare offers a different path: start with better collaboration and information sharing, then grow into a fully controlled environment at your own pace. By combining ease of use with deep shipbuilding expertise, eShare gives shipyards the benefits of PLM without the pain of a long, costly implementation.

Instead of being another complicated system, eShare and Wave provide a practical way to manage the shipbuilding lifecycle. They make it possible for shipyards to achieve traceability, consistency, and efficiency while still working in ways that feel familiar and manageable for their teams.