Digital twin software – the smarter way to manage engineering data

Overview

Drowning in data, lacking insight? Disconnected systems make it hard to act fast and make informed decisions when it matters most.

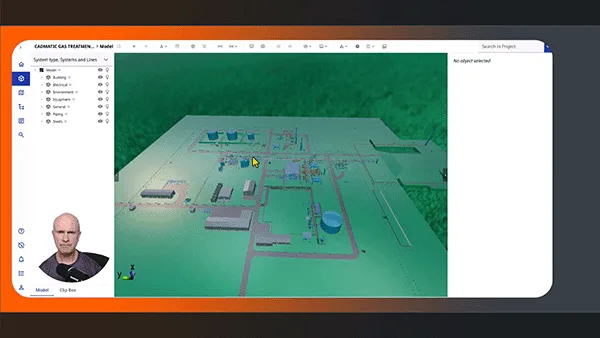

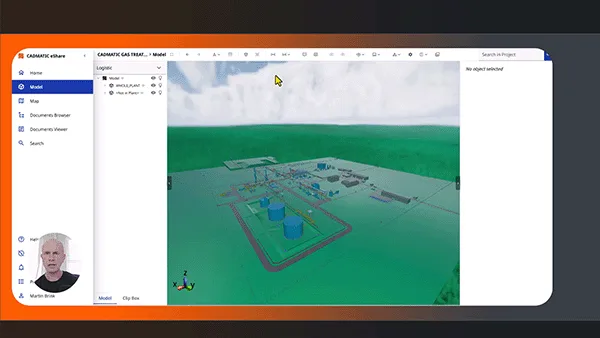

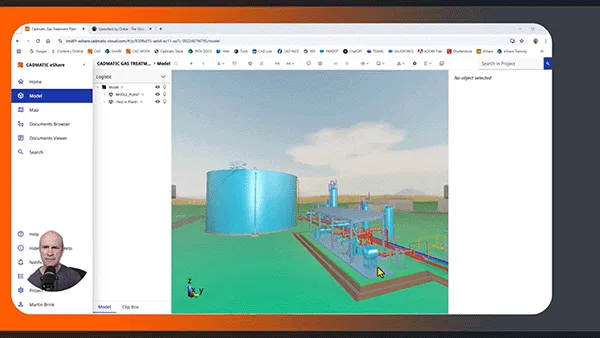

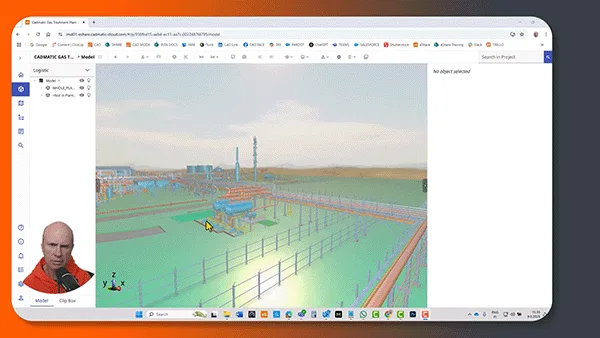

CADMATIC eShare transforms scattered data into actionable insights. It consolidates design models, documents, IoT data, and project metadata into an interactive, browser-based hub. Your complex project data will be accessible and understandable to everyone.

eShare is vendor agnostic, working seamlessly with design tools, databases, and document systems from various providers; giving you the freedom to build your digital twin your way. Whether you’re reviewing designs, planning maintenance, or monitoring progress, eShare gives you the right data in the right context – fast.

-

View federated 3D models with full data overlays

-

Link all documentation, drawings, and systems in one place

-

Empower stakeholders to explore and collaborate in real time

Benefits

-

Full context, fewer clicks

Combine 3D, 2D, and metadata for intuitive project understanding; no jumping between systems. -

Easy to access and use

Browser-based and highly visual, eShare requires minimal training for new users. -

Future-proof integration

Connects to almost any design tool, document management system, or database.

Features

-

Centralized project visibility for all stakeholders

Unite your design, docs, and data in one place. Gain clarity, stay in control, and keep your project on track.- Integrated 3D model and document viewing: Navigate your project with ease by visualizing 3D models alongside linked drawings, documents, and metadata in a single interface.

- Role-based access and collaboration: Give every stakeholder, from engineering to site teams, access to the right data at the right time, securely and efficiently.

- Web-based interface: No CAD tools needed. Access project data anytime, anywhere, with only a browser.

-

Real-time insights and traceability for better decisions

Track progress, issues, and changes visually to stay on top of project status and boost efficiency.- Issue and progress tracking: Monitor fabrication, installation, and inspection workflows with color-coded 3D views and detailed issue logs.

- Data linking and system integration: Connect your engineering, procurement, and project control systems to enrich the digital twin with live data.

- Change history and visual traceability: See exactly what changed, when, and by whom, with full visual context across model and documents.

-

Smarter data, faster twins

AI turns your visual data into a smart, interactive digital twin. Skip the manual work and get faster results with automated tag recognition.- AI-powered tag recognition: Turn visual data into structured intelligence with zero manual effort.

- Fast-track digital twin creation: Build accurate, interactive digital twins without needing a 3D model.

Want to dive deeper? Explore supported file formats

Read more

“When you visualize data in a realistic digital image of the plant, it dramatically improves the quality of information conveyed to the user. It gives the site management a much greater amount of information in a single screenshot. This assists the site management to take more effective operational decisions.”

Frequently asked questions

Can CADMATIC eShare be integrated with other systems?

Yes. eShare is designed for easy integration with a wide range of systems, including document management, ERP, maintenance, and inspection platforms. This allows organizations to link and visualize data from multiple sources within a single environment.

How does eShare support project and asset management?

eShare connects design, construction, and operational data in one interface. Users can visualize asset statuses, track progress, view related documents, and identify issues; all within the 3D model context. This improves transparency and enables more informed project and asset management decisions.

Is CADMATIC eShare suitable for remote work and site access?

Absolutely. As a browser-based platform, eShare enables users to access critical information and 3D models from any location, including construction sites and remote offices. This makes it ideal for distributed teams and field personnel who need real-time insights.

What is CADMATIC eShare?

CADMATIC eShare is a web-based digital twin platform that centralizes project and asset data from multiple systems. It provides a unified, visual environment for accessing 3D models, documents, and engineering data to support efficient decision-making across the project lifecycle.

Who can benefit from using CADMATIC eShare?

eShare is valuable for engineering companies, EPC contractors, asset owners, and operators. It enhances collaboration between stakeholders by offering up-to-date, shared access to project and asset data throughout the design, construction, and operational phases.